Why Powderless DTF Printer Is The New Trend In 2024?

2024-05-23

In the field of textile printing, innovation in printing processes and technologies has always been the key to promoting the development of the industry. However, with the continuous changes in market demand and the growing consumer demand for personalized, high-quality textiles, DTF printing technology has gradually revealed its limitations.

For example, although DTF (Direct-to-Film) printing presses meet market demand to a certain extent, their reliance on powder printing increases costs and puts considerable pressure on the environment. In addition, the pattern printed by DTF feels harder and has poorer air permeability than DTG printing.

Against this background, the new powderless DTF printing machine has become the new favorite in the textile printing field with its many advantages such as no need for powder, environmental protection and energy saving, and high-precision printing. This article will focus on what is a powderless DTF printer and how it will change the printing industry and become a new development trend in 2024.

Table of Contents

What is powderless DTF printer? No need to shake powder

Before understanding what a powderless DTF printer is, it is crucial to understand the working principle and basic knowledge of DTF printing. As explained in the article “What is DTF Printer”, a DTF printer, also known as a Direct-to-Film printer, is a technology that transfers ink from film to a printable surface.

Its working principle is to print the design pattern directly onto the PET film, then evenly sprinkle the hot-melt powder through a powder shaker, melt it at high temperature, and then dry it, finally, it is hot-pressed and attached to various types of clothing. However, during this powdering process, on the one hand, there will be problems of flying powder and being environmentally unfriendly; on the other hand, if the powdering is uneven, there will be powder residue on the edges.

The newly launched Powderless DTF printer can solve these problems very well. During the printing process, there is no need for a powder shaker or hot melt powder. The glue is used as a special adhesive to print directly on the film, and then Thermal transfer technology transfers patterns onto textiles. This printing method not only eliminates the powder shaking step in previous DTF printing but also greatly improves printing efficiency and is more environmentally friendly and energy-saving.

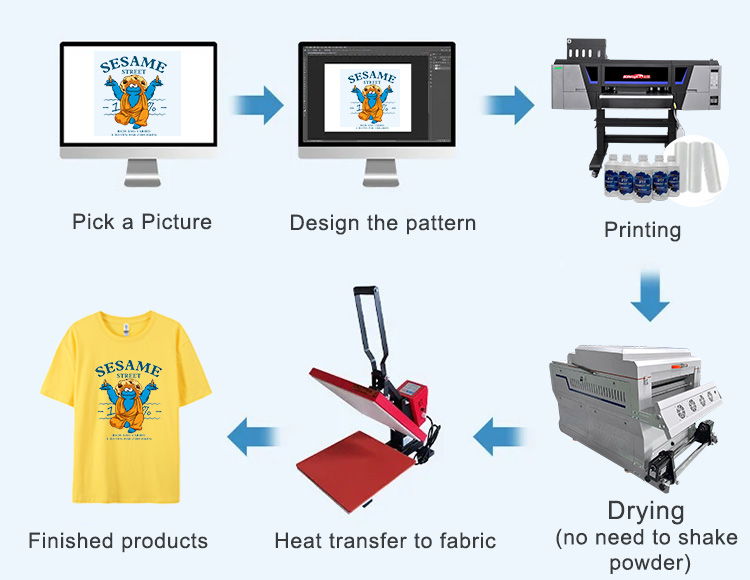

Printing process of Powderless DTF printer

Step 1: Design the Pattern

Process and edit the designed pattern through computer software, while ensuring that the designed pattern size is within the printing range of the printer.

Step 2: Printer prints pattern

The designed pattern is printed on a special film (DTF PET film) through a powder-free DTF printer. This film is usually used as a printing medium to make the pattern printing clearer.

Step 3: Heat Press Transfer

After cutting the printed pattern, place it on the surface of the material to be printed, and transfer the pattern to the target fabric through high-temperature pressing of a heat press.

Step 4: Peel off the film

After the hot pressing is completed, gently peel off the film to complete the entire printing process.

Advantages of Powderless DTF Printers

Compared with conventional DTF printers, the new powderless DTF printer has become the key to solving many difficulties in the textile printing field with its advantages of environmental protection and energy saving, higher efficiency, lower costs, good breathability, and high brightness.

Environmentally friendly: Compared with the traditional powder mode, the glue mode of the powderless DTF Printer reduces waste and smoke generation, is more environmentally friendly, and is also harmless to the human body.

More efficient: Without the powder shaking step, the machine has a simple workflow and can process orders quickly. This is very beneficial for mass production and urgent orders. KingJet’s powderless DTF printer can print 20 square meters of patterns per hour, 20% faster than similar products.

Reduced costs: By eliminating the need for excessive powder application, powderless DTF printers significantly reduce production costs. At the same time, this printing solution also saves work space. This cost-saving and environmentally friendly function will become a powerful choice for enterprises to maximize profit margins.

Good breathability: Using glue instead of powder printing can greatly improve the air permeability of the finished product. The pattern printing feels softer than conventional DTF printing.

High brightness: There is no need to use powder. When glue is used as a special adhesive glue with PET film, the ink transfer is clearer, and brightly colored and high-definition patterns can be printed on various materials.

Durable and long-lasting: Compared with conventional DTF printing, powderless DTF printers are more stretchable and do not use powder, which allows the ink to adhere more firmly to the printing fabric, so the printed pattern will be longer-lasting and more durable.

Application of powderless DTF printer

The new powderless DTF printer is suitable for printing on various textile materials due to its environmental protection, bright colors, and good breathability. Whether it is pure cotton, polyester, or other complex fabrics, it can be easily processed. At the same time, it can also be used in fields such as personalized customization, brand promotion, and gift production. For example, personalized customization of T-shirts, exquisite gift packaging production, etc., to meet the diverse needs of the market. Bring unlimited creativity and possibilities to your printing business.

The difference between powderless DTF printer and DTF printer

Each type of printer has its advantages and disadvantages. The most obvious difference between powderless DTF printers and DTF printers is that they do not need to shake powder and are more environmentally friendly and energy-saving. The following table compares their differences in more detail.

| Printer Type | Powderless DTF printer | DTF printer |

| Equipment | printer, curing machine | printer, powder sharker, curing machine |

| Printing Method | transfer without powder | transfer using excessive powder |

| Touch Feeling | soft and comfortable | hard and grainy |

| Breathability | good | bad |

| Printing Speed | no shaking powder, higher speeds | shaking powder reduces print speed |

The development prospects of powderless DTF printers

As people’s demand for environmentally friendly, energy-saving, personalized, and high-quality textiles continues to increase, the development prospects of powder-free DTF printers are very broad. In the future, powder-free DTF printers will continue to optimize printing technology, improve production efficiency, reduce production costs, and be applied in more fields. At the same time, with the continuous advancement of technology and changing market demand, powder-free DTF printers will continue to introduce new functions to meet market demand.

Conclusion

The powderless DTF printer is not only a technological innovation in the field of textile printing, but also a powerful driving force to promote the development of the printing industry in a green, efficient, and high-quality direction. This revolutionary printing equipment abandons the reliance of traditional DTF printers on powder and leads the textile printing industry towards a more environmentally friendly future with its unique powder-free design.

In the field of digital printing, King Jet is also constantly advancing with the times, exploring more environmentally friendly and intelligent DTF printing solutions. If you want to know more about new DTF development trends, contact the professional KingJet team now!

FAQ

What Consumables are needed for powderless DTF printer printing?

Requires printer, dryer, DTF ink, glue, and PET film for use.

powderless DTF printer VS DTF printer the most obvious feature?

Using glue instead of hot melt powder is more environmentally friendly and the printing is more vivid.

What is the printing process of powderless DTF printer?

Design pattern – Printing – Drying (no need to shake powder) – Heat press transfer – Finished product.

Does a powderless DTF printer cost more?

No, the powderless DTF printer does not require a powder shaker and hot melt powder, which greatly reduces production costs.