what is DTF printer?

2024-04-16

DTF printer (direct-to-film printer) is a machine used to print the designed patterns directly on the film. It brings an unprecedented printing experience to the clothing industry and provides a multi-functional and efficient printing solution.

It can meet the needs of small-batch personalization as well as mass production. This article will give you a better understanding of DTF printers from the following aspects:

Table of Contents

What is DTF printer?

The DTF printer’s full name is “Direct to Film Printer”, which transfers patterns from film to various material surfaces. It is an innovative digital printing technology equipment, especially suitable for clothing heat transfer.

It breaks through the limitations of traditional printing technology, has no need for plate making, engraving, and other complex processes, and has no minimum order quantity restrictions, the real realization of a piece of order, and zero inventory.

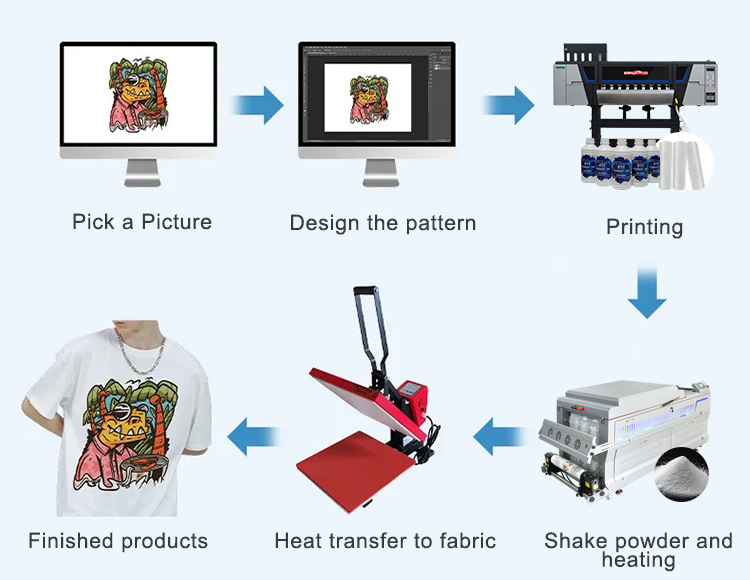

Working Principle of DTF Technology

DTF is mainly used in the clothing and textile industry, its working principle is to design the pattern on the computer first, print the pattern directly on the PET film through the printer, then sprinkle the hot melt powder evenly on the pattern, and then melt and dry it at high temperature, and finally press the pattern on the garment by heat press machine, which will complete the printing of the garment.

What fabrics can DTF be printed on?

DTF printing breaks through the limitations of traditional printing methods and is widely used in various fabrics, such as cotton, denim, polyester, nylon, wool, cotton and linen, silk, etc.

How does DTF printer work?

The operation process of a DTF printer is simple and does not require any pre-processing steps. The main workflow of the DTF printer is as follows:

Step 1: Design images. Use professional design software CADLink, photoprint, maintop, etc. to edit images.

Step 2: The printer prints the image onto the transfer film.

Step 3: Sprinkle powder and curing images. The powder shaker evenly spreads the hot melt powder on the image and curing process.

Step 4: Heat press transfer. A heat press machine transfers the pattern from the transfer film to the fabric. The temperature of the heat press machine is generally set between 135°C~165°C, and the pressing time is about 10~15 seconds.

Step 5: Tear off the transfer film. After the heat press transfer is completed, gently tear off the transfer film. At this time, the pattern has been successfully transferred to the fabric.

Pros and cons of DTF printer

Pros:

1、Applicable to almost all fabrics, it is the “universal printing machine” in the clothing industry.

2、Short preparation cycle, fast printing, no need for pre-treatment

3、Compared with DTG printing, more durable, and washes color fastness up to 4-5 levels

4、Compared with traditional printing technology, it is environmentally friendly, energy-saving, and reduces waste generation

5、Support personalized customization and small batch production

6、Easy to operate, one person can operate multiple machines

Cons:

1、DTF printing effect is not as soft as DTG printing.

2、Color vividness is slightly lower than sublimation printing.

Equipment required for DTF (direct to film) printing

DTF PET Film

Mainly used in the heat transfer process, the DTF printer prints the pattern on the PET film and then transfers it to various materials through high-temperature heat pressing. PET film is divided into single-sided coating film and double-sided film. According to the temperature, it is also divided into cold peel film and hot peel film.

Heat press machine

Utilizing high temperature and pressure, the pattern on the PET film is attached to the target material. It has the characteristics of easy operation, high transfer efficiency, and high pattern quality.

FAQ

DTF printing process?

Print the designed pattern on the PET film, then evenly sprinkle hot melt powder on the pattern, melt it at high temperature and then dry it, cut the PET film pattern, and heat-press the pattern onto various types of clothing through heat press, and then you can complete the clothing printing.

What fabrics can DTF technology be applied to?

Any fabric which can stand 170℃ heat press temperature can be transferred by DTF, like cotton, T-shirts, jeans, canvas, sweatshirts, polyester, etc.

How long will the print last on the garment? How many times will it be washed?

Under normal wear and standard washing operations, DTF print can usually withstand approximately 50 to 100 washing cycles in accordance with the international washing standard.

What is the print cost for DTF?

Print cost for 1 sqm transfer fabric pattern is about 1-2 usd, and about 0.07-0.1usd for A4 size Printing.