What Is Powderless DTF Printing (No Powder DTF)?

Author : KingJet

2024-07-17

Now in 2024, powderless DTF printing technology has become popular. With it, you don’t need to apply and solidify DTF powder, and you don’t need to shake the powder. Without the powder layer, it also avoids the problem of inferior texture and poor breathability of printed patterns.

Therefore, powderless DTF printing is vigorously promoted by everyone. It is a new technology for printing clothing textiles and other textile fabrics. Let’s discuss this emerging technology together.

Table of Contents

What is powderless DTF printing?

Powderless DTF printer (direct-to-film printers), as the name suggests, is a major improvement in the powder-shaking link of traditional DTF printing technology. Traditional DTF printers need to use hot melt powder (DTF powder) during the printing process to ensure that the pattern can be firmly attached to the fabric.

In contrast, powderless DTF printers abandon the step of shaking powder and directly use printing glue adhesive instead of hot melt powder in traditional DTF printing, thereby avoiding powder residue and dust problems that may occur during printing, achieving a more efficient and environmentally friendly printing method.

For more details about powder-free DTF machines, please check out this article: KingJet KJ-604 powderless DTF printer.

Principle of powderless DTF printing technology

The technical core of no-powder DTF printers lies in their unique printing method and material selection.

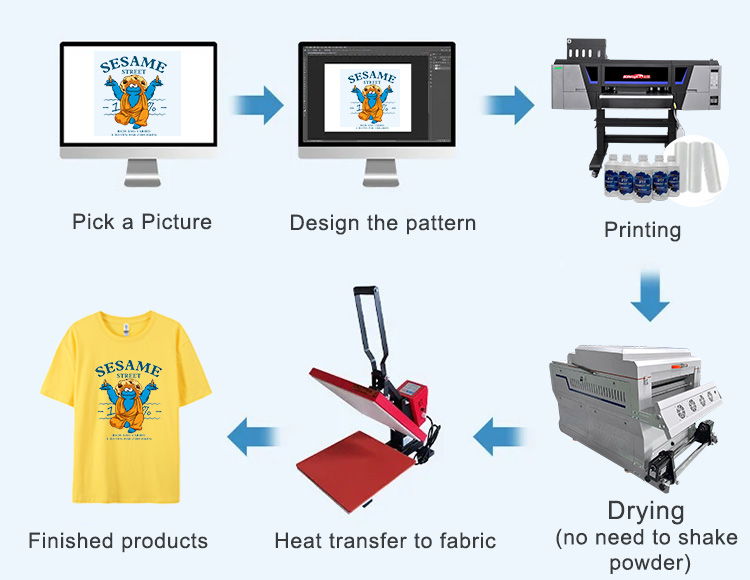

During the printing process, the no-powder DTF printer first prints the designed pattern directly onto the dedicated printing material PET film through digital inkjet technology, and then uses special glue adhesive to firmly attach the pattern to the target fabric or other materials, and finally completes the product printing through hot pressing transfer.

This process does not require hot melt powder, which greatly simplifies the operation process, reduces dust pollution, and improves printing efficiency and pattern quality.

Step 1: Design the pattern

Design the pattern on the computer and ensure it is within the printable range.

Step 2: Printing with a powder-free DTF printer

Use a powder-free DTF printer to print the pattern on the PET film, use glue adhesive instead of powder, and there is no need to shake the powder.

Step 3: Heat press transfer

After printing, cut the pattern and place it on the hot press machine. The pattern can be transferred to fabrics such as T-shirts or sweatshirts through temperature and pressure.

Advantages of powderless DTF printing

Easy operation: no powder shaker and oven are required, which reduces equipment investment operation steps and labor costs.

Cost savings: Powder-free DTF printers do not require the use of powder, significantly reducing production and printing costs.

Environmentally friendly and healthy: avoids the use of hot melt powder, reduces dust pollution, and is more friendly to the environment and the health of operators.

Good printing effect: Due to the use of advanced printing technology and high-quality glue adhesive, the patterns printed by the powder-free DTF printer are bright in color, rich in details, soft to the touch, and have high color fastness and waterproofness.

Wide range of applications: No powder DTF printers are not only suitable for various fabrics, such as cotton, polyester, linen, denim, etc. but can also print on a variety of materials such as leather and nylon, greatly broadening the application field.

Higher production efficiency: Compared with traditional DTF printers, the powder-free DTF process is simpler and the printing speed is increased by 20%, which means that you can produce more prints in a shorter time, which is very beneficial for large-scale production and emergency orders, further improving profitability.

Application of powderless DTF printing

Powderless DTF printers have a wide range of applications, mainly in the clothing and textile industry.

Clothing industry: Powderless DTF printers can easily print various patterns on T-shirts, sweatshirts, denim, and other clothing to meet the needs of personalized customization and mass production.

Advertising promotion: Print advertising patterns on promotional materials such as advertising shirts, cultural shirts, and eco-friendly bags to enhance brand image and publicity effects.

Home decoration: Print patterns on home furnishings such as pillows, curtains, and carpets to increase the comfort and beauty of the home environment.

Gift customization: Print personalized patterns on gifts such as umbrellas, backpacks, and shoes to meet consumers’ customization needs.

The difference between no powder DTF printer and DTF printer

Powderless DTF printers are more innovative and have more differences than DTF printers. Here are some of their differences:

| Printer Type | Powderless DTF printer | DTF printer |

| Printing Method | transfer without powder | transfer using excessive powder |

| Required Equipment | printer, curing machine | printer, powder sharker, curing machine |

| Printing Speed | no shaking powder, higher speeds | Normal speed, shaken powder increases the printing time |

| Touch Feeling | soft and comfortable | Poor hand feel |

| Breathability | good | bad |

| Printing color | Printing clarity | Enhance color vividness |

| Eco-Friendly | Yes | No, there may be a problem with powder flying |

Is powder-free DTF printing suitable for you?

Whether powderless DTF printing is suitable for you depends mainly on your specific needs, business type, and expectations for print quality.

If you value environmental protection and want to reduce dust pollution in the production process and pursue efficient production and high print quality, powderless DTF printing is undoubtedly a good choice for individuals and enterprises.

If you are a beginner and have limited funds, considering the initial investment cost of powder-free DTF printing equipment, the consumption cost of ink or glue adhesives, and cost-effectiveness and market demand, powder-free DTF printers may not be suitable for you. You may consider a startup-friendly A3 desktop DTF printer.

Conclusion

As a major innovation in modern printing technology, powderless DTF printers are gradually changing the production model of the printing industry with their environmentally friendly, efficient, and high-quality printing performance.

It not only solves the dust pollution problem generated in the traditional printing process, provides a more environmentally friendly and sustainable printing technology, but also simplifies the printing process and improves production efficiency, bringing significant cost savings and competitiveness improvements to enterprises.

In the future, powderless DTF printers will continue to be an innovation and development of DTF printing technology, bringing more surprises and possibilities to the printing industry.

I hope the above knowledge about powderless DTF printing can provide you with value. If you want to know more about no-powder DTF printers, please contact the professional KingJet team now.

FAQ

What Consumables are needed for powderless DTF printer printing?

Requires printer, dryer, DTF ink, glue, and PET film for use.

powderless DTF printer VS DTF printer the most obvious feature?

Using glue instead of hot melt powder is more environmentally friendly and the printing is more vivid.

What is the printing process of powderless DTF printer?

Design pattern – Printing – Drying (no need to shake powder) – Heat press transfer – Finished product.

Does a powderless DTF printer cost more?

No, the powderless DTF printer does not require a powder shaker and hot melt powder, which greatly reduces production costs.