What is All-in-One Direct-to-Garment Embroidery Machine (DTE)?

Author : KingJet

2024-11-07

Integrating embroidery technology into direct-to-garment technology (DTG) can add extraordinary texture and layers to products and create an innovative channel for the T-shirt textile industry to increase revenue. While promoting order growth, direct-to-garment embroidery machines have a core advantage in competition with screen printing or other embroidery machines with unique printing methods.

Table of Contents

What is all-in-one direct-to-garment embroidery machine?

The integrated direct-to-garment embroidery machine is a multifunctional device that integrates pure cotton direct-to-garment DTG printing technology and embroidery technology.

The embroidery machine specifically embroiders the white pattern area on the fabric, while the DTG (Direct-to-Garment) technology is responsible for printing the corresponding color areas. The pattern printed by combining these two technologies has strong color expression, rich texture, and a good imitation embroidery effect.

For more configuration details about this all-in-one direct-to-garment embroidery machine, please check out this article: Integrated DTG & Embroidery Machine.

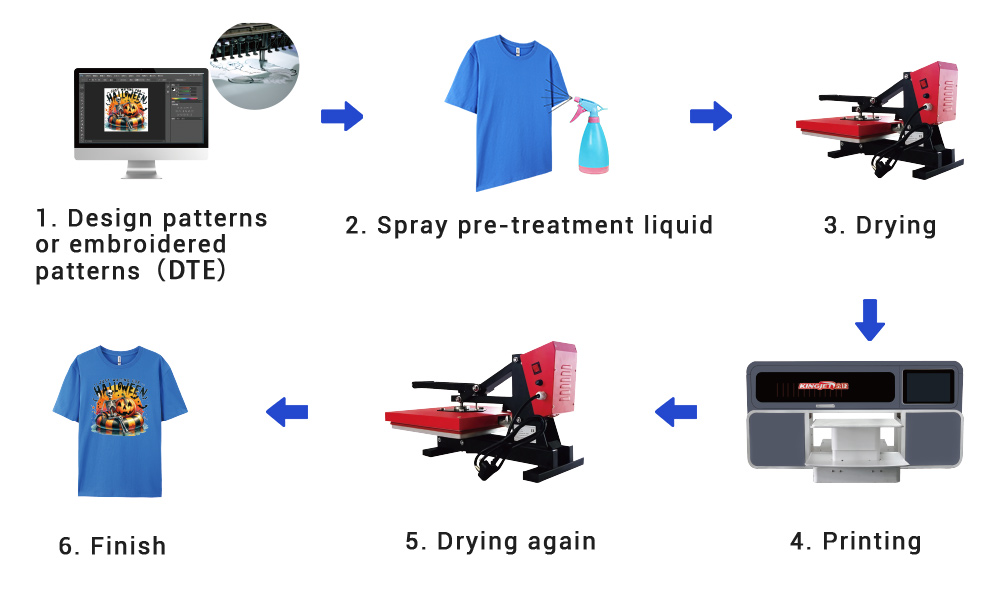

Working principle of direct-to-garment embroidery machine

1. Design pattern

Use professional printing design software to create direct-to-garment embroidery patterns.

2. Spray pretreatment liquid

Spray a layer of pretreatment liquid on the clothes to improve the adhesion and color saturation of the ink on the fabric. The role of the pretreatment liquid is to penetrate the fiber, so that the ink can be better absorbed and fixed during printing.

3. Drying

After spraying the pretreatment liquid, the clothes need to be dried by a heat press to allow the pretreatment liquid to completely penetrate the fiber and evaporate excess water, which is conducive to subsequent printing and embroidery work.

4. DTG printing and embroidery

The embroidery machine is mainly responsible for embroidering white or light-colored patterns, and DTG prints colorful or gradient patterns.

5. Re-drying

After completing DTG printing and embroidery, the garment needs to be dried again. This ensures that the ink is completely dry and fixed in the fiber. The surface of the clothes will be flatter and smoother after drying, and the pattern will be more three-dimensional.

Application of direct-to-garment embroidery machine

The all-in-one direct-to-garment embroidery machines are widely used in the fields of clothing customization and textile decoration. The following are several main application scenarios:

Corporate garment customization

The all-in-one direct-to-garment embroidery machine can provide personalized embroidery patterns and decorations for corporate T-shirts, sweatshirts, uniforms, and other garments. The colorful patterns are printed by DTF technology, while the core corporate logo or lettering section is beautifully embroidered.

Home decoration

Integrated direct-to-garment embroidery machines are also widely used in home decoration. For example, DTG is responsible for multi-color printing on home furnishings such as pillows, curtains, and carpets and then embroidering with exquisite personalized patterns and decorative details.

Gift customization

The integrated DTG and embroidery machine are unique in the field of gift customization. Colorful or complex patterns on textiles such as hats, bags, and scarves are printed by DTG, and then personalized blessings or important details through embroidery, which shows the unique meaning of the gift.

Fashion design

The emergence of integrated direct-to-garment embroidery machines allows designers to explore new creative designs. Printing regular patterns through DTG technology and embroidering more eye-catching details make the product unique.

Advantages of direct-to-garment embroidery machine

The integrated DTG and embroidery machine has many advantages over traditional garment customization and textile decoration methods:

Innovative embroidery

The combination of DTG and embroidery can perfectly solve the problem of the embroidery machine printing multiple colors or gradient colors and the multiple requirements of the thread category. The embroidery machine only needs to embroider white thread, and the color part is done by the DTG printer, which saves a lot of different color embroidery threads and can easily meet the user’s multi-color requirements.

Strong three-dimensional pattern

Combining direct-to-garment DTG and embroidery technology can significantly enhance the visual effect of the garment. The color printing part is integrated with the texture details in the embroidery, with good color expression and a strong three-dimensional sense.

Enhanced durability

Embroidery technology is to embroider exquisite patterns directly on the fabric with needles, which have extremely high wear resistance. Therefore, when embroidery is added to DTG printing, the pattern will be more durable and can still maintain a good appearance even after multiple washings.

Personalized customization

The all-in-one direct-to-garment DTG and embroidery machine can print and embroider unique pattern textures, fonts, and colors for users, making your garments and textiles more upscale and high-quality.

Conclusion

The emergence of the integrated direct-to-garment embroidery machine solves the need for embroidery machines to print multi-color threads and can provide unique patterns and decorations for personalized clothing and textiles, bringing new vitality to the clothing customization industry.

In addition, KingJet is an 18-year professional digital printer manufacturer, if you want to know more about an all-in-one direct-to-garment embroidery machine, welcome to contact the professional KingJet team.

FAQ

Who is the integrated DTG and embroidery machine suitable for?

The products printed by combining DTG and embroidery machines have the characteristics of unique craftsmanship, good color expression, more eye-catching, and enhanced durability. They are suitable for fashion designers, embroiderers, graphic designers, and individuals and companies who need personalized garments and textile decoration to print differentiated products and enhance the purchase value of products.

Will the patterns printed and embroidered by the all-in-one direct-to-garment embroidery machine fade or fall off?

No, embroidery technology is to sew the pattern into the fabric, which is extremely durable. Its addition will make the pattern printed by DTG more durable and not easy to fall off.

What are the advantages of integrated direct-to-garment embroidery machine compared to DTG?

1. Better visual effect of patterns

The patterns printed by DTG will be single, while integrated DTG and embroidery machines will be printed by DTG with bright patterns, and important details and textures will be embellished by embroidery, which will make the products more novel and have better visual effects.

2. More durable

The patterns printed by direct-to-garment technology will inevitably fall off after long-term washing. The addition of embroidery technology will make the patterns more durable and friction-resistant.

3. Enhance market competitiveness

Embroidery is added into the DTG technology, which can be personalized with various patterns, logos, and details, making them more unique, and high-quality to enhance the market competitiveness.