Maximize Your Business Profits With Integrated Gold Stamping UV DTF Printer

Author : KingJet

2024-09-06

Gold stamping, also known as foil stamping/hot stamping, is a common decorative process in the packaging and printing industry. It mainly changes the visual appeal of crystal labels by applying metal foil effects, resulting in a unique and eye-catching gloss and luxurious visual effects. This not only adds personality to your product but also enhances the overall visual impact of the product.

Reading this article, you will learn more about the uniqueness of the integrated hot stamping UV DTF printer and why it can increase your business profits.

Table of Contents

What Is Integrated Gold Stamping UV DTF Printer?

First, let’s start with the UV DTF printer. The UV DTF printer, also known as the UV sticker printer, is an advanced digital printing method that uses UV curing ink to print patterns directly on a dedicated AB transfer film.

This technology has been widely used in packaging, personalized gifts, and other fields with its bright colors, rich details, strong weather resistance, and the ability to transfer to a variety of flat and curved materials.

The integrated gold stamping UV DTF printer is a product that has been fully upgraded and innovated based on the traditional UV DTF printer. It not only retains all the advantages of UV DTF printers but also integrates the functions of automatic laminating and peeling off the waste film and gold foil, making the entire production process more efficient and convenient.

Specifically, the integrated gold stamping UV DTF printer can automatically complete the operation of laminating and peeling off the waste film and gold foil without an additional laminator, which greatly saves labor and time costs. At the same time, by peeling off the waste film to remove the glue residue, the transfer effect of the pattern is cleaner and flatter, and the application range is therefore wider.

To learn more about integrated gold stamping UV DTF printers, you can check out this article: gold stamping UV DTF printers.

Printing Process Of Gold Stamping UV DTF Printer

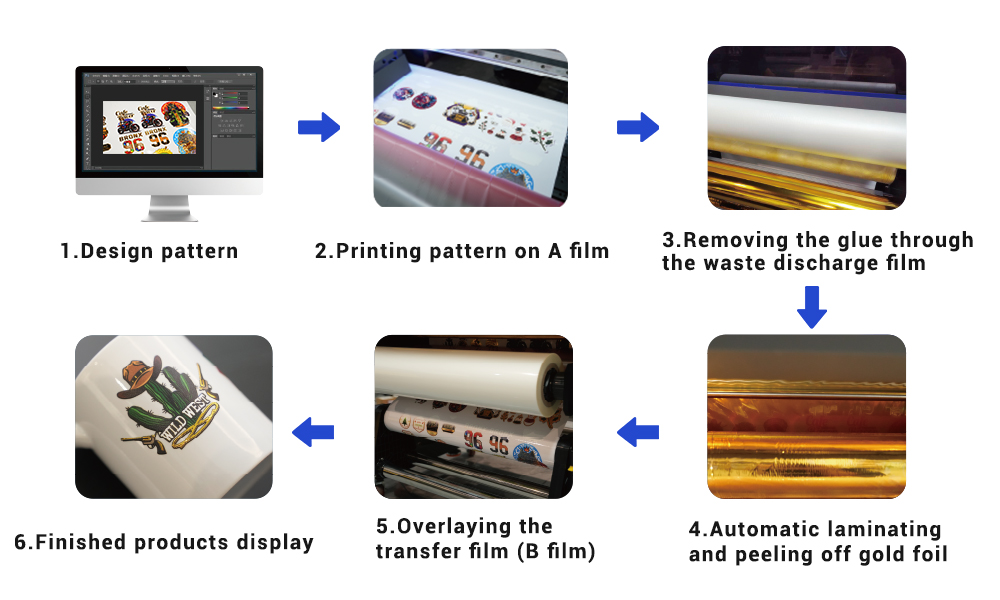

The printing process of the integrated gold stamping UV DTF printer is highly automated. From design to finished product, every step is accurate and correct, which greatly improves production efficiency and product quality. The following is a detailed workflow:

Step 1: Design the pattern

First, you need to draw the desired pattern in the design software and adjust it to the best effect. These patterns can be in various forms such as text, graphics, photos, etc., and can be customized according to your needs.

Step 2: Print the pattern on the A film and laminate the waste film

The integrated hot stamping UV DTF printer prints the designed pattern on the A film and then laminates the waste film.

Step 3: Automatically peel off the waste film and remove the glue

The printer automatically peels off the waste film (removes the excess glue layer and uncured ink) through a precise mechanical structure to ensure the cleanliness and neatness of the pattern. This step not only removes the glue residue but also prepares for the subsequent hot stamping operation.

Step 4: Automatically laminate and peel off the gold foil

The integrated hot stamping printer then automatically laminates and peels the gold foil. The gold foil is precisely attached to the pattern to form a dazzling golden decoration. Subsequently, the excess gold foil fragments will be automatically peeled off, leaving a perfect hot stamping effect.

Step 5: Automatically laminate the transfer film (B film)

To protect the pattern and facilitate subsequent transfer, the printer will press another layer of transfer film (B film) on the surface of the pattern. This film not only protects the pattern but also makes the transfer process smoother.

Step 6: Cut the pattern

Cut according to the transferred pattern for subsequent transfer.

Step 7: Tear off the A film and stick it on the surface of the object

Tear off the A film of the pattern just cut (at this time, the pattern has been firmly adhered to the B film through the glue layer). Then, stick the pattern on the surface of the object to ensure that the pattern fits tightly with the object.

Step 8: Press firmly and tear off the B film

By pressing evenly, the pattern is tightly combined with the surface of the object. Finally, tear off the B film and the hot stamping product transfer is completed, showing bright colors and bling-bling hot stamping visual effects.

Unique Advantages Of Gold Stamping UV DTF Printers

Efficient automation

Non-traditional foil stamping printers do not require manual lamination, fully automated operation, unattended or minimal human intervention, greatly shortening the production cycle and improving production efficiency.

Low cost of personalized customization

The integrated gold stamping UV DTF printer supports small batches and multiple varieties of personalized customization, without the need for cumbersome processes such as plate opening and plate making, greatly reducing production costs and customization thresholds. This allows you to easily meet the diverse needs of customers and enhance market competitiveness.

Good hot stamping visual effect

Whether it is a metallic font, pattern, or a complex and varied texture effect, it can be perfectly presented through the UV DTF hot stamping process. This unique hot stamping visual effect not only adds a sense of luxury and class to the product but also invisibly enhances the added value and market competitiveness of the product.

Wide application

The integrated gold stamping UV DTF printer supports the transfer of a variety of materials, including ceramics, peeling, leather, metal, paper, plastic, and various irregular planes and curved surfaces. Such as transfer on acrylic, thermos cups, mobile phone cases, suitcases, glass cups, ceramic cups, etc. This wide range of applications allows you to easily cope with various complex production needs and expand your business scope and application areas.

Ceramics

Acrylic

Glass

Plastic

Gift Box

Metal

Application Of Gold Stamping UV DTF Printer

The application scope of the integrated gold stamping UV DTF printer is extremely wide, covering almost all industries that require high-quality hot stamping custom printing. The following are some typical application areas:

Packaging industry

Provide exquisite packaging and printing services for various commodities to enhance the grade and added value of products. For packaging and printing needs in industries such as wine labels, food, cosmetics, and electronic products, hot stamping packaging is more eye-catching.

Personalized gifts

Customize various personalized gifts, such as photo albums, mobile phone cases, water cups, key chains, etc., to meet the personalized needs of consumers. With the hot stamping effect, the uniqueness and value of the gifts can be highlighted, and consumers’ desire to buy can be enhanced.

Industrial manufacturing

Provide printing services such as logos and decorations for products in the fields of automobiles, electronics, and home appliances. After adding the hot stamping process, the products are more high-end and can enhance market competitiveness.

Commercial industry

It can be applied to printed materials such as trademarks, logos, business cards, and greeting cards. The hot stamping effect is noble and elegant, with a strong metallic texture and high wear resistance, which can attract customers’ attention and enhance the brand image.

Conclusion

In the field of continuously developing printing technology, the integrated gold stamping UV DTF solution will gradually occupy a central position, providing the printing industry with new creativity and unlimited printing possibilities.

It can not only significantly improve production efficiency and effectively control costs, but also take the lead in fierce market competition and maximize your business profits.

If you are interested in this gold stamping UV DTF printer, you can contact the professional KingJet team to get free samples or provide relevant suggestions.

FAQ

What is the difference between this integrated gold stamping UV DTF printer and other UV DTF printers?

The integrated gold stamping UV DTF printer automatically laminates and peels off the waste film and gold foil during the printing process, without manual operation, saving time and effort.

In addition, after peeling off the waste film to remove the glue, the application range is wider and can meet various creative packaging designs.

Can UV DTF print T-shirts?

UV DTF printing is not suitable for printing directly on fabrics such as T-shirts. Because the UV ink used in UV DTF printing does not adhere well to the fabric fibers, it may peel or crack over time.

If you need to print T-shirts, you can choose a professional T-shirts printer such as a DTF printer or a DTG printer, which KingJet provides.

How durable is the UV DTF printed pattern?

UV DTF printers use special UV inks, and the printed patterns have good scratch resistance, light resistance, and water resistance, so the patterns can remain stable and durable for a long time.

What is the difference between UV DTF and DTF?

UV DTF is more suitable for transfer printing on various hard surfaces, while DTF is good at printing on textile soft surfaces such as T-shirts and hoodies.

UV DTF printers mainly use UV ink and AB film, while DTF printers use DTF film, DTF powder and DTF ink.

UV DTF printers rely on UV light and integrated lamination technology, while DTF printers require powder and oven drying.