KingJet KJ-1908 Industrial Large Format Sublimation Printer

Professional large-format industrial sublimation printer with excellent performance and vivid colors, providing unlimited printing creativity for sportswear, garments, curtains, flags, tents, carpets, and other fabrics.

Key Features:

1. High-speed printing, maximum speed up to 300sqm/h.

2. 1.5L ink cartridges, 2.5L secondary ink cartridges, and 15L reserve ink bottles ensure long-term high-speed printing.

3. Dual THK silent guide rails, three-stage pinch roller, and more stable printing.

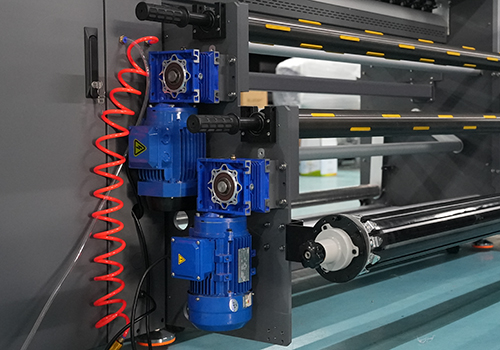

4. Industrial-grade super-power feed-up and take-up system, realizing fast and efficient take-up.

Configuration Highlights:

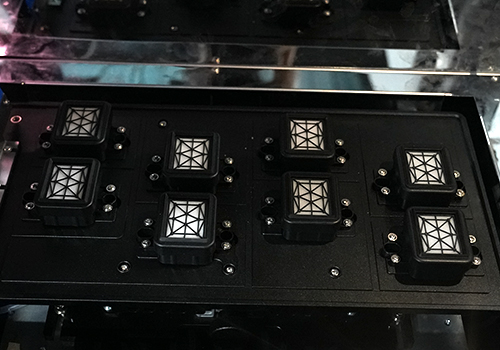

- Printhead: 8*EPSON I3200-A1

- Printing Mode: 1pass: 300m²/hr; 2pass: 160m²/hr

- Max Printing Width: 1900mm

- Max Material Weight: 400KG

- Color: 4 Colors (C, M, Y, K) (optional: FY, FM, LC, LM)

KJ-1908 Industrial sublimation printer details List

KJ-1908 Large Format Sublimation Printer video

KJ-1908 Industrial Sublimation Printer Features

Front and rear circulation oven

The front and rear two-stage internal circulation oven with intelligent temperature control system for better drying and more powder saving.

Good printing feathering effect

2*4 staggered arrangement, better feathering effect between nozzles, perfectly eliminating splicing marks.

Magnetic levitated linear motor

Ensures more stable movement of the trolley frame and higher printing accuracy.

Intelligent variable speed control system

The printing speed can be freely controlled to ensure smoother paper collection and release.

Three-color fault light

When the machine fails, runs out of ink or runs out of paper, it will automatically alarm, making it more user-friendly.

Large-capacity ink supply system

The 15L large-capacity ink bottle can supply ink for long-term large-volume printing needs.

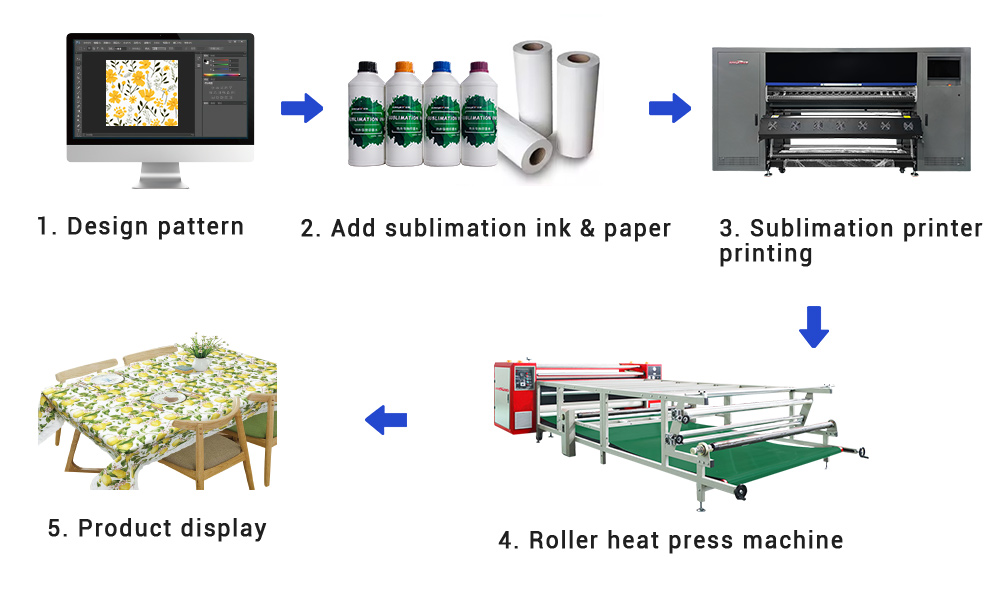

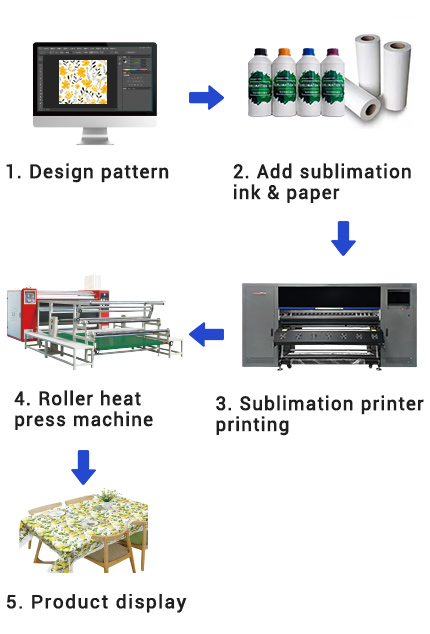

Large Format Industrial Sublimation Printer Printing process

Product Specification

| Product | Industrial Sublimation Printer |

| Model | KJ-1908 |

| Printhead | 8*EPSON I3200-A1 |

| Printing Mode | Productivity |

| 1 Pass | 300m²/hr |

| 2 Pass | 160m²/hr |

| Max Material Width | 2000mm |

| Max Printing Width | 1900mm |

| Material Gram Weight | Minimum 32g/m² |

| Max Material Weight | 400KG |

| Max Roll Diameter (Feed) | 500mm |

| Drying Method | Infrared Radiation |

| Ink Type | Sublimation ink |

| Color | 4 Colors (C, M, Y, K) (optional: 6 colors, 8 colors) |

| Ink Volume | 5L/bottle |

| Printing Material | Sublimation paper, titanium oxide paper, wallpaper |

| Rated Voltage | AC220±10% |

| Rated Power | 10KW |

| Working Environment | Temperature range: 20-30℃, humidity range: 46-65% |

| Machine Size | 3360*1300*1750mm |

| Packing Size | 3410*1240*1780mm |

Get In Touch With Us

Large Format Industrial Sublimation Printer Applications

With its unique printing technology and excellent printing effect, industrial sublimation printer can be used in interior decoration, personalized home furnishing, textile and clothing manufacturing, advertising, and exhibition, such as sportswear, printed carpets, curtains, pillowcases, umbrellas, canvas, etc.

Sweatshirt

Dress

Flag

Pillow

Tablecloth

Curtain

FAQ

What is sublimation printing?

Sublimation printing is a digital printing technology, also known as thermal transfer printing. The working principle is to use heat energy and pressure to transfer dyes to different materials.

What equipment do I need for sublimation printing?

For sublimation printing, you will need a sublimation printer, sublimation ink, paper designed for sublimation, and roller heat press machine.

Sublimation printer VS inkjet printer, what is the difference?

Sublimation printers produce prints that are more durable and less prone to fading than inkjet printers.

Sublimation printing transfers the dye into the substrate rather than depositing it on the surface, so the resulting image is more permanent.

How long does clothes printed with sublimation last?

Sublimation printing works by converting solid dyes directly into a gas when exposed to high temperatures, and then ejecting the gas onto the print medium.

So when the fabric is heated, the dye sublimates turns into a gas, and fuses directly into the fabric. When the dye is embedded in the actual fibers, it creates a permanent print that won’t crack or peel over time.

What is the difference between dye sublimation printer and DTF printer?

1. Material Application Range

The dye sublimation printing technology is mainly suitable for light-colored or white polyester fabrics. The more polyester content, the brighter the color printing effect.

DTF printing technology can print on almost all types of fabrics, including natural and synthetic fiber materials such as cotton, polyester, nylon, etc.

2. Print Quality

Sublimation printing technology directly penetrates the dye into the fabric fiber through high temperature and pressure, and the printed image has high durability and is not easy to fade or peel off.

DTF (direct-to-film) printing technology prints the image on a PET film and then transfers the image to the fabric by heat pressing. The print quality may be slightly inferior to sublimation technology, but the color of DTF-printed images will be more vivid.

3. Printing Efficiency

The sublimation printing process requires precise temperature and time control, so the printing speed may be slow.

The process of DTF printing is relatively simple, supports fast printing and batch printing, and is very suitable for large-scale production.

4. Touch

The pattern printed by the dye sublimation printer is integrated with the clothing, and it is almost imperceptible that an image is attached to the surface. It feels soft and breathable.

Although the DTF printer printed area feels relatively soft, its breathability may be slightly worse than thermal sublimation printing.

5. Applicable Market

Dye sublimation printers are particularly suitable for occasions that require high-quality image printing, such as sportswear, swimsuits, yoga clothes, and other clothing with good breathability requirements, as well as banners, flags, jerseys, and home textiles.

DTF printers are more suitable for the clothing printing market, especially on occasions that require fast, efficient, and high-quality printing.

Do I need heat press machine for sublimation?

Yes, a roller heat press machine is required for sublimation printing, and the image output is better and more durable after being processed by the roller heat press.

Related products

1.8m Sublimation Printer

1.8m medium width, 1-4 EPSON I3200 printheads optional, multiple intelligent color management system, print image colorful, suitable for printing personalized textile customization, decorative paintings, large posters, banners, art reproductions and so on.

Related Consumables

Sublimation Ink

- Smooth printing, no clogging.

- Strong weather resistance and no color loss.

- Suitable for printing on a wide range of materials.

- Bright transfer colors, high image clarity, and rich details.

One-Stop Services

Comprehensive service starting from pre-sale to after-sale to help your business on track.

Free Printing Sample

To show the quality and capability of our printer to satisfy your needs, we will send you a free video demonstration showing its operation. And you can get free samples for consumables.

Fast Delivery

To meet everyone’s order quickly, we have established branches in many places around the world, saving transportation time. Products in stock usually ship within 3-5 days.

Lifetime service

You can enjoy one-year warranty on the main components of our brand machines, lifetime service for the entire machine operation, free after-sales consultation, and 24-48 hours technical support services.

payment method

In order to meet your various payment needs, we can accept many payment methods, such as TT, PayPal, credit card, letter of credit, western union, moneygram, etc.

Start Your Business

Contact us anytime for professional and personalized services.