DTF Transfer Film Main Features

- Easy to peel off without residue.

- Stick the powder evenly and shake it clean.

- High color reproduction and strong color expression.

- Uniform coating, strong ink absorption, and no ink flow.

- The heat transfer pattern has strong stretchability and is not easily deformed.

Related Parameters

Film Sizes: A3, A4, 30/40/60/120cm*100m

Film Type: hot peel film, cold peel film, instant DTF film, single side film, double side film, etc.

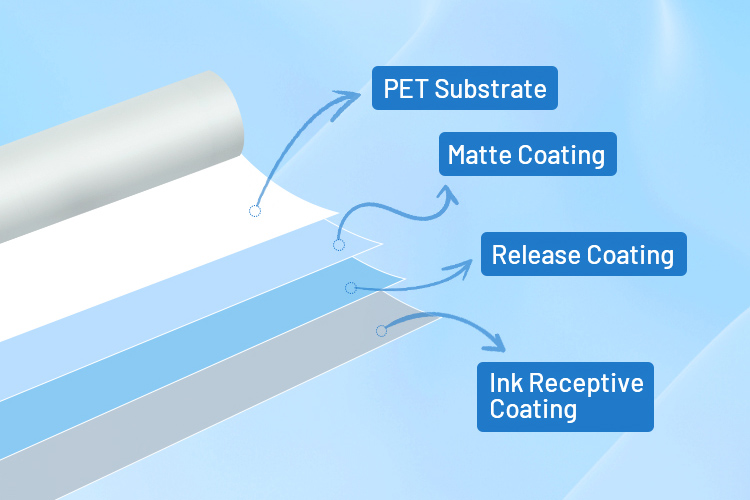

KingJet DTF PET Film Structure

DTF PET Film Structural Principle

DTF film (DTF PET film) is mainly composed of a PET substrate, an ink-absorbing layer, a release layer, and auxiliary coatings (such as antistatic and anti-blocking layers).

- Breathability.

- Cold and hot peeling version.

- Good ink absorption.

- High temperature resistance.

- Excellent peeling performance.

- matte, glossy, and frosted effects.

Classification of KingJet DTF Transfer Films

DTF films can be categorized based on their tearing method: hot-peel film, cold-peel film, instant-peel film, and instant-press and peel film. The main differences lie in tear-off time, ease of operation, applicable fabrics, and production efficiency. Hot-tear films offer high efficiency, cold-tear films have good stability, instant-tear films are even faster, and instant-press-instant-tear films represent the ultimate in rapid processing.

Instant Peel DTF Film

Features:

- Fastest film peeling speed, extremely high efficiency.

- Strict timing is required; slight delays may affect the results.

- More suitable for mass production lines.

- Pressure Setting: 0.4MPa-0.6MPa.

- Temperature Setting: Approximately 160℃ (adjust according to fabric type and thickness)

- Heat Pressing Time: 8s-12s.

- Peeling Time: Wait 2 seconds after heat pressing before peeling (can also be hot-tear or cold-tear)

- Pattern Placement: Place the pattern in the center within 3cm of the edge of the heat press plate.

Hot Peel DTF Film

Features:

- Reduces cooling time, enhancing batch production efficiency.

- Delivers high surface gloss, ideal for large-scale patterns.

- Requires precise temperature and pressure control; peeling after cooling may cause adhesive residue or pattern damage.

- Pressure Setting: 0.4MPa-0.6MPa.

- Temperature Setting: Approximately 160℃ (adjust according to fabric type and thickness)

- Heat Pressing Time: 8s-12s.

- Peeling Time: Peel off 10 seconds after heat pressing.

- Pattern Placement: Place the pattern in the center within 3cm of the edge of the heat press plate.

Cold Peel DTF Film

Features:

- Easier film removal, better stability.

- Mattly finish, more natural colors.

- Suitable for rough or special fabrics (such as canvas, fleece, coated fabrics).

- Pressure Setting: 0.4MPa-0.6MPa.

- Temperature Setting: Approximately 160℃ (adjust according to fabric type and thickness)

- Heat Pressing Time: 8s-12s.

- Peeling Time: Peel after cooling

- Pattern Placement: Place the pattern in the center within 3cm of the edge of the heat press plate.

Instant Press & Peel DTF Film

Features:

- Reduces cooling time, enhancing batch production efficiency.

- Delivers high surface gloss, ideal for large-scale patterns.

- Requires precise temperature and pressure control; peeling after cooling may cause adhesive residue or pattern damage.

- Pressure Setting: 0.4MPa-0.6MPa.

- Temperature Setting: Approximately 160℃ (adjust according to fabric type and thickness)

- Heat Pressing Time: 2s-3s.

- Peeling Time: After heat pressing, wait 2 seconds before peeling off.

- Pattern Placement: Place the pattern in the center within 3cm of the edge of the heat press plate.

KingJet DTF Transfer Film Specifications

| Name | DTF Transfer Film/DTF PET Film |

| Main Material | PET |

| Type | hot peel film, cold peel film, instant DTF film, single side film, double side film, etc. |

| Original Film Thickness | 75um (standard shipment) |

| Thickness After Coating | 80-81um (single-sided film); 82-83um (double-sided film) |

| Number of Coatings (excluding original film layer) | 4 layers (single-sided film); 5 layers (double-sided film) |

| Diameter and Length | 13cm (for 100 meters of material) |

| Standard Sizes | A3, A4, 30/40/60/120cm*100m |

| Standard Packaging | 1/2/4 rolls/box; 100 sheets/pack, A3/10 packs/box, A4/20 packs/box |

| Net Weight | 7-7.1kg |

| Gross Weight | 7.5-7.6kg |

| Curing System | UV LED curing system |

| Applications | T-shirts, hoodies, shoes, hats, pillows, workwear, home decor, various textiles, etc. |

| Note | Double-sided film can only be printed on the printing side; the back cannot be printed |

KingJet DTF Film Storage and Expiration Date

1. Please store the product in a cool and dry place. Avoid contact with sharp objects. If unused after opening, seal tightly and store to prevent moisture and high temperatures.

2. Under normal storage conditions and in unopened packaging, the product has a shelf life of approximately one year. After the expiration date, it can continue to be used if a test is passed.

3. Optimal storage conditions: Temperature 25℃-28℃, Humidity <50%.

KingJet DTF Transfer Film Makes Your Textile Printing Easier

DTF (Direct to Film) film is a transfer material used in textile digital printing, composed of a PET substrate, a hot melt adhesive layer, and a release film.

Its operating principle involves printing the pattern onto the DTF film using a DTF printer, and then transferring the pattern to the surface of various fabrics (such as cotton, polyester, and blends) using a heat press machine.

Compared to traditional screen printing and heat transfer technologies, DTF film has advantages such as vibrant colors, strong adhesion, wide applicability to materials, and no need for plate making, making it widely used in clothing printing, shoe decoration, bag customization, and and home decoration.

Frequently Asked Questions

Why is my DTF film running ink?

Reason:

1. There are powdery impurities or pressure marks, which are prone to ink flow.

2. Check if the front heating plate is turned on after printing.

3. If both colour and white inks fail to adhere to the film, check whether the film is installed correctly.

Solution:

When encountering slightly poor overall ink absorption effect and ink flow, you can try:

1. Reduce the proportion of white ink settings and appropriately decrease the amount of white ink.

2. Increasing the heating and drying temperature of the printer can also improve the pass rate.

3. Heating the heating plate can help activate ink and reduce ink flow.

4. Check if the DTF film is installed incorrectly.

Is the DTF film shaking powder not clean?

Reason:

The weather is humid, with high humidity and static electricity. If the edges of the pattern are shaking and not clean, it is necessary to check:

1. Is the environmental humidity too high or the temperature too low?

2. Is the power of the DTF shaker machine insufficient?

3. Whether powder application was delayed excessively after printing, causing drying and glycerol diffusion?

4. Is there flying ink on the nozzle?

Solution:

If it is found that the pressure wheel position is shaking unclearly or the blank area is shaking unclearly, it should be due to the influence of static electricity or the DTF rubber powder is damp or the DTF powder is too fine or the shaking force is insufficient. Measures should be taken according to the situation.

2. Generally, increasing the temperature of the heating plate and the receiving position of the shaking machine after printing, as well as increasing the shaking force, can help reduce the phenomenon of unclean edge shaking.

DTF film perforation during baking?

Reason:

High-temperature, short-time baking causes the water and glycerin in the ink to boil and evaporate violently, opening up the pores in the coating and film.

Solution:

It is best to use a mixture of medium and fine powders as the main component, with a small amount of coarse powder mixed in, or even none at all. A high-quality DTF dryer with a long drying cycle in both low and high temperature sections yields the best results. This allows for a gradual drying process, thoroughly evaporating the oil and water and melting the adhesive without causing a violent reaction.

The resulting DTF film is flexible, elastic, smooth, and well-dryed. If the DTF dryer is of slightly lower quality, utilize the preheating function of the heating plate to preheat and evaporate some moisture, thereby reducing the burden. It is advisable to dry the film slightly before applying the powder.

Is your DTF film experiencing oil or moisture seepage?

Reason:

The dried or transferred pattern may show oil or water seepage.

Solutions:

1. This problem is due to insufficient drying, preventing the water and glycerin in the printing ink from drying completely, resulting in backflow.

2. The drying capacity of DTF powder is also limited by the length of the dryer. Increasing the drying temperature slightly on the receiving plate before the powder baking machine can help evaporate the water and glycerin earlier.

Powder shedding after DTF film transfer?

Reason:

After DTF heat transfer, the coating peels off in the blank areas around the pattern.

Solution:

This is caused by excessive heat transfer pressure damaging the ink-absorbing layer on the film, or by the fabric surface paste easily sticking to the coating.

Generally, this can be easily solved by ensuring the temperature and heat transfer time meet the requirements for a firm adhesion, and by reducing the pressure as much as possible.

DTF pattern shows ghosting, misalignment or paper slippage?

Reason:

This is attributable to an inadequate step design in the machine’s film-feeding mechanism, which fails to fully accommodate the functional requirements of single-sided film.

Solution:

The slipperiness of the single-sided film’s reverse side interferes with the equipment’s operational state. Typically, such machinery necessitates the use of double-sided film; once the friction provided by the matt-coated reverse side is engaged, normal operation is immediately restored.

DTF film peeling at the edges?

Reason:

Temperature too high or heat transfer time too long.

Solutions:

Reducing the heat transfer temperature or shortening the heat transfer time.

Other DTF Consumables

Start Your Business

Contact us anytime for professional and personalized services.