the Best DTF Printers For Your Business

DTF printers can print on almost all textile fabrics, making them the most popular technology for printing T-shirts and other products.

- Only $0.2 printing cost.

- 18 years professional printer manufacturer, top quality, highly cost-effective.

- Optional Print Width: A3/42cm/60cm/80cm/1.2m DTF printer/powderless DTF printer.

- Optional Printhead: EPSON XP600、I1600、I3200.

- Wide application: Any fabric that can stand 170℃ heat press temperature can be transferred by DTF, like T-shirts, cotton, jeans, polyester, canvas, nylon, etc.

Leading and trusted DTF printer Manufacturer/Supplier

Quality

Durable and rigorously tested that lasts over 50-100 washes.

Price

Factory direct sales, quality assurance, and high cost-effectiveness!

OEM/ODM

18 years Professional factory, strong self-research capabilities, meet your personalized design.

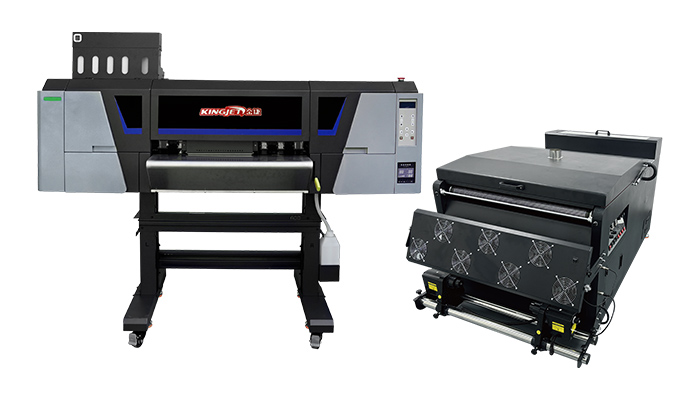

KingJet DTF Printer List

small size DTF printer - Friendly to Beginners

Specially designed for business beginners, compact and flexible, affordable, and cost-effective.

- A2 (42cm) printing width

- 2 * EPSON XP600/I1600/I3200 printheads optional.

- 5 Colors (CMYK+W)

- Integrated design, printing-powder shaking-drying in one, flexible and efficient.

- Small footprint, full functions, stable printing.

- Round white ink circulation stirring system.

- Suitable for small businesses and entry-level customers to DIY print T-shirts.

- A3 printing width

- 1 * EPSON XP600 printhead

- 5 Colors (CMYK+W)

- White ink circulation function

- Nozzle automatic cleaning system

- Compact and flexible, easy to operate.

- Suitable for DIY printing T-shirts at home.

- Small batch production, suitable for business beginners.

- 12-inch/42cm printing width

- 2 * EPSON XP600/I1600/I3200 printheads optional.

- 5 Colors (CMYK+W)

- White ink circulation stirring system.

- Shaking powder intelligent heating system.

- Industrial grade high-precision platform 0-0.5 mm to guarantee flat printing.

- Suitable for those who are looking for cost-effective and small to medium-width printing.

Medium size DTF Printer - High quality

High-performance, stable, fast, multi-color printing, large-scale printing.

- 60cm/24-inch printing width

- 3/4 pcs EPSON I3200 printheads

- 5 Colors(CMYK+W)+ glue

- Printing speed increased by 20%.

- Use glue adhesive instead of hot melt powder, which is more eco-friendly.

- Printing T-shirts is softer and more breathable.

- Easy to clean and maintain.

- 60cm/24-inch printing width

- 4 * EPSON I3200 printheads

- Multiple printing solutions: 9 colors, 13 colors, and powderless glue solutions.

- Multiple humanized and convenient settings.

- Suitable for those who require stable printing and convenient operation.

- 60cm/24-inch printing width

- 2 * EPSON I3200 printheads

- 5 Colors(CMYK+W)

- High performance, fast printing

- Environmental Smoke Purifier

- Upgraded oil drain to prevent oil stains from flowing everywhere.

- Suitable for those who pursue fast and high-quality printing.

- 60cm/24-inch printing width

- 4 * EPSON I3200 printheads

- 9 Colors(CMYK+W, RGBO and neon colors available)

- Faster and higher precision printing.

- Sealed powder circulation system

- Suitable for personalized printing and multi-color printing.

- 60cm/24-inch printing width

- 5 * EPSON I3200 printheads

- 5 Colors (CMYK+W)

- Environmental Smoke Purifier

- Extremely fast printing speed and high printing accuracy.

- Suitable for printing large quantities of T-shirts for urgent orders.

- 60cm/24-inch printing width

- 6 * EPSON I3200 printheads

- 9 Colors (CMYK+W, FM, FY, O, G)

- Unprecedented printing speed and precision.

- Multi-color scheme to enhance color expression.

- Perfect combination of efficiency, high quality, and creativity.

Large format DTF printer - Professional & High Production

Suitable for professional clothing manufacturers to industrialize and mass produce T-shirts or other textiles.

- 80cm/31″ printing width

- 4 * EPSON I3200 Printheads

- 9 Colors(CMYK+W,RGBO and neon colors available)

- Larger width, high-quality printing.

- Shake powder heating circulation system.

- Suitable for large-scale production of T-shirts and hoodies.

- 1.2m/47″ printing width

- 8 * EPSON I3200 Printheads

- 5 Colors (CMYK+W)

- Silent dual rail for smoother printing.

- The extended arc-shaped front heating platform has a better heat conduction effect.

- Suitable for industrial-grade professional garment manufacturers to print clothing and textiles.

Why is DTF printer the best choice for printing T-shirts and other textiles?

- No pre-treatment required

- Brighter colors

- More durable

- More flexible designs

- Suitable for almost all fabrics

- Simple printing process

Steps: Print – shake powder – dry – heat transfer – product completed

Professional & Reliable DTF Printer Manufacturer/Factory

Leading digital printer manufacturer for 18 years, also the first batch of R&D DTF printer in China, hot selling DTF printer, UV DTF printer, UV flatbed printer, sublimation printer, eco-solvent printer, and related consumables, insisting on providing high-end and stable machines as well as professional team service.

Valuable market guidance

Deeply rooted in the digital printing industry, with branches in the United States, Peru, and multiple agents around the world, in addition to price advantages, KingJet will also provide your business with the latest industry information and market development trends.

High-end quality

The Printer components are all from top global suppliers, plus professional R&D and technical teams rigorously inspect the machines before shipment to ensure stable performance.

Full customization

First-class R&D capabilities, support OEM/ODM, meet your needs for diversified customization, and bring more potential opportunities for your business.

Comprehensive guidance

Our professional technical team and engineers provide comprehensive pre-sales, in-sales, and after-sales consulting services. Whether it is machine training or troubleshooting, they have rich experience to make your printing process worry-free!

DTF printing machine Application

DTF printing is an ideal printing tool in the clothing field. It can be applied to various dark or light clothing fabrics, such as pure cotton, polyester, nylon, treated leather, denim, silk, etc. It can also be applied to non-clothing fields, such as shoes, hats, canvas bags, umbrellas, tablecloths, etc.

Hoodies

T-Shirt

Denim

Shoes

Umbrella

Canvas Bag

Essential consumables for DTF printing

DTF Ink

DTF Powder

PET Films

FAQ

Is the voltage selectable?

Currently, our KingJet DTF printer uses a single-phase power source. You only need to tell us your local single-phase voltage and plug standard, and we will customize the machine according to your needs. 110V and 220V voltage are available.

What is the printing cost of DTF printer?

The DTF printer print cost for a 1 sqm transfer fabric pattern is about 1-2 USD and about 0.07- 0.1 USD for A4 size printing.

What is the difference between DTF printing and screen printing?

DTF printing does not need to make template samples like screen printing; meanwhile, DTF can do much more complicated pattern printing work, which screen printing cannot.

How long will the print last on the garment? How many times will it be washed?

Under normal wear and standard washing operations, DTF print can usually withstand approximately 50 to 100 washing cycles following the international washing standard.

One-stop service

Comprehensive service starting from pre-sale to after-sale to help your business on track.

Free Printing Sample

To show the quality and capability of our printer to satisfy your needs, we will send you a free video demonstration showing its operation. And you can get free samples for consumables.

Fast Delivery

To meet everyone’s order quickly, we have established branches in many places around the world, saving transportation time. Products in stock usually ship within 3-5 days.

Lifetime service

You can enjoy one-year warranty on the main components of our brand machines, lifetime service for the entire machine operation, free after-sales consultation, and 24-48 hours technical support services.

payment method

In order to meet your various payment needs, we can accept many payment methods, such as TT, PayPal, credit card, letter of credit, western union, moneygram, etc.

Start Your Business

We would love to speak with you.

Contact us anytime for professional and personalized services.