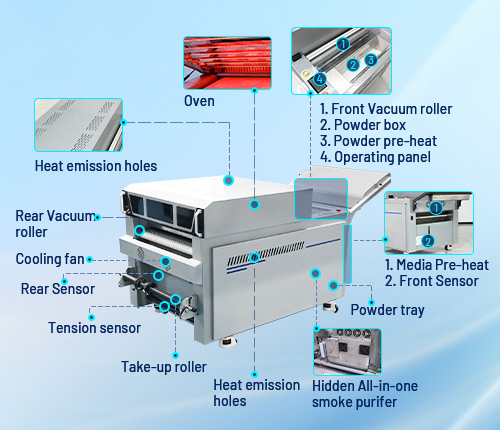

KingJet DTF Powder Shaker Machine With Smoke Purifier

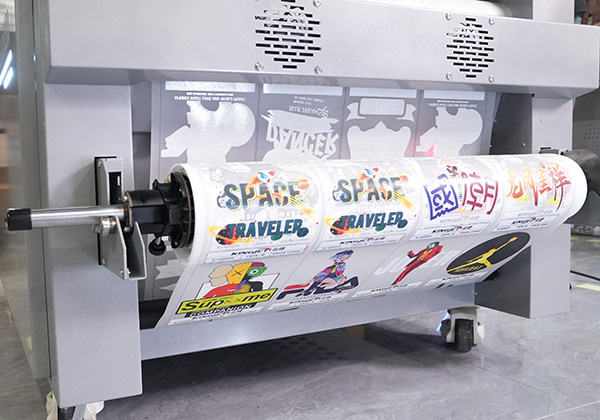

KingJet’s fully automatic powder shaking machine is an efficient and energy-saving back-end processing equipment designed for the DTF printing process.

It automatically completes the powder spreading and vibration powder recovery process on printed PET film through high-frequency vibration and an intelligent heating system, achieving high-quality effects of zero smoke, zero oil leakage, and no white edges, perfectly matching the high-speed printing production line.

Key Highlights:

1. Ultra-Low Power Consumption: Optimized heating system and energy-saving design, saving 60%-70% energy compared to conventional powder shakers on the market.

2. Fully Automatic Operation: One-button start, automatically completing the entire process of feed-up film, powder shaking, heating, and take-up film.

3. Reduced Labor Costs: Easy to operate, fully automated, saving 1-2 workers for every five machines.

4. High-Speed Matching: Shaker speed synchronizes with high-speed DTF printers, seamlessly connecting and improving overall production capacity.

5. Environmentally Friendly: The Hidden smoke purification system effectively filters volatile substances.

6. Narrow Door Compatibility: Model A650 fits through 76cm narrow doors after removing the outer casing; Model A6501 fits through 81cm narrow doors after removal.

DTF Powder shaker machine Video

DTF Powder Shaker Detailed Configuration

DTF Powder Shaker Features

Upper and lower double rows of high-efficiency heating lamps

Combined with our unique smart heating solution, our machine can save at least 5 kw of power compared to other brands’ powder shaking machines.

High-frequency vibrating powder removal device

The device is quiet, but it has a better powder-shaking effect, so that the final pattern does not appear with white edges.

Suction rollers

The patented design of our suction rollers significantly enhances the adsorption force, ensuring smooth film transport and good temperature control, thereby substantially extending the service life of the fan.

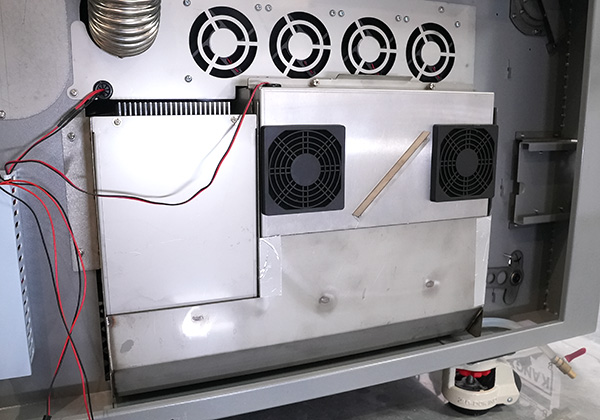

Hidden All-in-one smoke purifier

The hidden smoke purifier effectively filters all smoke, meets the world’s environmental standards, and more space-saving, suitable for indoor enclosed spaces such as shopping malls and shops.

Smart touch Operation screen

Automatic mode and manual mode are optional; the machine operates in automatic mode, completely hands-free. One person can efficiently operate three machines at the same time, which greatly reduces labor.

Tension take-up device

To ensure neat and orderly take-up, our newly improved automated take-up system allows printing to be completed without human intervention.

60cm/24-inch DTF powder shaker Specifications

| Model | A650 | A6501 |

| Compatible Model | KJ-602 | KJ-604、KJ-604pro |

| Compatible with Printing Speed | 12 m²/h | 23 m²/h |

| Power | 2 KW, 220V/110V | 2.4 KW, 220V/110V |

| Compatible with PET Film Widths | Below 65cm (80cm, 90cm, and 120cm powder shakers are also available) | |

| Shaking Mode | Motor Vibration, and Automatic Powder Return-Free | |

| Heating Method | Bake the powder before and after, with fast and constant temperature heating | |

| Take-Up and Feed-Up | Constant tension automatic sensing system | |

| Operating Mode | Manual mode/automatic mode/ | |

| Built-in Smoke Purifier | Equipped | |

| Automatic Deceleration of Film Replacement | Yes | |

| Shaking Method | Constant weight automatic sensing | |

| Net Weight of the Machine | 188kg | 270kg |

| Package Weight | 274kg | 392kg |

| Machine Size (L*W*H) | 1385*870*930 mm | 2162*850*935 mm |

| Package Size (L*W*H) | 1480*1030*1220 mm, 1.86 CBM | 2290*980*1210 mm, 2.715 CBM |

1.3m DTF powder shaker Specifications

| Model | 1.3m DTF Powder Shaker |

| Power | ≈6KW |

| Baking Efficiency | up to 50m/h |

| Shaking Powder | motor vibration, automatic powder return-free |

| Heating Method | back baking and front baking, fast constant temperature heating |

| Take-up and Feed | constant tension automatic induction system |

| Operating Mode | manual control/auto control |

| Mesh Belt | drum suction operation mesh belt |

| Automatic Deceleration of Film Cutting | prevent deformation of the heating film |

| Method of Dusting | constant weight automatic sensing |

| Configuration | with an all-in-one hidden smoke purifier (optional) |

| Machine Weight | 357.5KG |

| Package Weight | 492.5KG |

| Machine Size | 1980x1690x1020mm, CBM: 3.4 |

FAQ

What is a DTF powder shaker? What is its main purpose?

The DTF powder shaker is a key device for the DTF printing process. Its main function is to evenly shake the hot melt powder onto the printed PET film (transfer film) to ensure that the powder accurately covers the pattern area.

Its core purpose is to prepare for the subsequent drying and pressing process to achieve a firm combination of the pattern and the fabric.

Compared with other powder shakers, what are the advantages of the KingJet DTF powder shaker machine?

1. The most cost-effective DTF Shaker on the market, with low energy consumption and cost savings. Every five units save 1-2 workers to operate, and each machine saves 60-70% energy compared to machines of the same specifications.

2. The first shaker with an integrated smoke purifier, the first automated shaker, and the first and only low-power DTF shaker on the market.

3. Fully automated, first adjust the drying speed according to the printing speed to ensure uniform drying, and secondly, automatically start and stop according to the printing situation, so that the film will not be baked yellow or wrinkled when the printer is paused. It also has a weight sensing function. When the powder is insufficient, it will automatically add powder. When the powder is insufficient, it will have a powder shortage alarm light and automatic powder return.

What is the basic operation process of the DTF powder shaking machine?

The operation of the KingJet DTF powder shaker machine is very user-friendly and is divided into automatic mode and manual mode.

Automatic mode:

1. Connect the power cord, turn on the machine power

2. Turn on heat function

3. Wait for the oven temperature to rise to the set value.

4. Place the DTF transfer film on the suction roller.

5. Turn on the vacuum function and the shaker function at the same time, so that the powder is evenly spread on the film.

6. Start the automatic mode for shaker drying (need to adjust the two sides of the shaker stopper to prevent the powder from falling too fast)

Manual mode:

1. Turn on the heat function, and the heating lamp in the oven will gradually turn on automatically.

2. Then turn on the shaker powder function (only when the powder cover is closed, because when the powder cover is opened, the powder shaking function will automatically stop).

3. Finally, turn on the suction function and the take-up function.

Notes on using the DTF powder shaker:

1. The value of powder weight should be set higher than 50, if it is lower than 30, the machine will pause feeding.

2. The front media sensor needs to detect the film in front, when the “X1” in the IO setting turns gray, it means the sensor has detected the film.

What do I need to pay attention to for daily maintenance of DTF Printer powder Shaker?

1. Daily cleaning: It is recommended to clean the inside of the upper oven once a week to remove residual oil stains and prolong the life of the machine.

2. Regular checking: whether the vibration parts, filters and sensors are normal or not, etc.

How to choose the right DTF powder shaker machine for you?

1. Production scale: daily production demand determines the size and speed of the machine.

2. Budget: Choose the basic model or extended model according to the economic ability.

3. Functional requirements: whether you need additional functions such as automatic film closing, multi-power adjustment, low power consumption, etc.

One-Stop Services

Comprehensive service starting from pre-sale to after-sale to help your business on track.

Free Printing Sample

To show the quality and capability of our printer to satisfy your needs, we will send you a free video demonstration showing its operation. And you can get free samples for consumables.

Fast Delivery

To meet everyone’s order quickly, we have established branches in many places around the world, saving transportation time. Products in stock usually ship within 3-5 days.

Lifetime service

You can enjoy one-year warranty on the main components of our brand machines, lifetime service for the entire machine operation, free after-sales consultation, and 24-48 hours technical support services.

payment method

In order to meet your various payment needs, we can accept many payment methods, such as TT, PayPal, credit card, letter of credit, western union, moneygram, etc.

Start Your Business

We would love to speak with you.

Contact us anytime for professional and personalized services.