Main Features

- Soft touch, high color adhesion.

- Excellent wash resistance.

- Anti-scratch and anti-yellowing.

- Diverse particle sizes to meet different printing needs.

- Wide compatibility: can be printed on cotton, nylon, chemical fiber and other materials.

Related Parameters

- Types: white powder, black powder, fine powder, medium powder, etc.

- Capacity: 1kg/bag

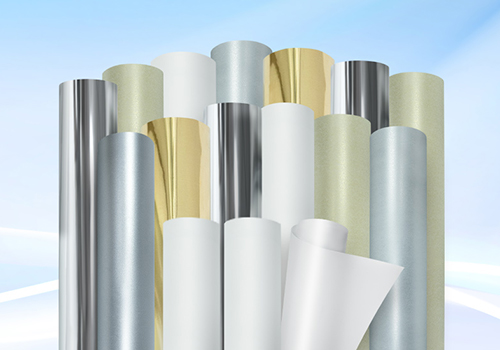

Classifications Of KingJet DTF Hot Melt Powder

DTF powder (Direct to Film Powder) is the core consumable in the DTF (Direct to Film) printing process, usually made of thermoplastic polyurethane (TPU) or other polymers in the form of fine particles.

Its core function is to evenly spread on the printed transfer film, melt it after heating, and build a permanent adhesive layer between the printed pattern and the fabric, ensuring that the pattern is accurately transferred from the DTF PET transfer film to the textile fabric.

KingJet offers a wide variety of DTF powders, including white DTF powder, black DTF powder, fine DTF powder, and medium DTF powder, to meet your various textile printing needs.

Anti-Sublimation White DTF Powder

- Particle size: 100-200μm

- Features: A specially formulated powder containing activated carbon to prevent sublimation after heat pressing. It effectively prevents sublimation and bleeding of dark or dyed fabrics at high temperatures, ensuring the purity and brightness of the white ink layer.

- Heat pressing temperature: 160°C for 6 seconds, with pressure set to four or above.

- Applications: Suitable for dark polyester, sportswear, jerseys, and other fabrics prone to sublimation.

Anti-Sublimation Black DTF Powder

- Particle size: 80-170μm

- Features: A specially formulated powder containing activated carbon to prevent sublimation after heat pressing. It shields against dye sublimation, avoiding the base color from showing through and enhancing pattern contrast.

- Heat pressing temperature: 160°C for 6 seconds, with pressure set to four or higher.

- Applications: Commonly used on dark polyester, black, or dark-colored base fabrics, especially for sportswear and workwear.

Ultra-Fine DTF Transfer Powder

- Particle size: 0-80μm

- Features: Extremely fine particle size, excellent softness, strong adhesion, suitable for lightweight fabrics, and unchanged fastness after washing.

- Heat pressing temperature: 160°C for 6 seconds, pressure setting at level four or above.

- Applications: Suitable for lightweight fabrics such as silk, chiffon, lightweight T-shirts, and other lightweight clothing.

Medium-Fine DTF Transfer Powder

- Particle size: 80-170μm

- Features: Balancing adhesion and softness, wide applicability, natural hand feel of finished products, and unchanged color fastness after washing.

- Heat pressing temperature: 160°C for 6 seconds. Pressure setting: four or above.

- Applications: Widely used in various textile printing, such as T-shirts, hoodies, canvas bags, polyester blended clothing, etc.

Medium DTF Adhesive Powder

- Particle size: 100-200μm

- Features: Slightly larger particle size, strong bonding power, excellent elasticity, and superior wash resistance. Withstands 60°C washing with detergent without wrinkling, deformation, or colour loss, demonstrating excellent colour fastness.

- Heat pressing temperature: 160°C for 6 seconds, with pressure set to level four or higher.

- Applications: Suitable for thicker fabrics such as denim, heavyweight cotton, and outerwear.

- Note: Store in a dry, well-ventilated area, avoid damp conditions, and direct exposure to sunlight.

Silicone DTF Hot Melt Powder

- Particle size: 100-200μm

- Features: Excellent adhesion to silicone materials, solving the problem of ordinary powder easily falling off silicone surfaces.

- Heat pressing temperature: 160℃ for 6 seconds, with pressure set to level four or higher.

- Applications: Suitable for waterproof fabrics, silicone-coated fabrics, functional sportswear, or garments with special processes.

Reduce White Ink DTF Powder

- Particle size: 100-200μm

- Features: After melting, it appears white, improving coverage and brightness, reducing white ink usage, and lowering production costs.

- Heat pressing temperature: 160℃ for 6 seconds, with pressure set to level four or above.

- Applications: Suitable for textile printing requiring substantial white ink usage, such as colourful patterns on white or light-coloured fabrics, including promotional T-shirts and team uniforms.

Low-Temperature DTF Hot Melt Powder

- Particle size: 100-200μm

- Features: Low melting point, melts at lower temperatures, protecting heat-sensitive fabrics from damage.

- Heat pressing temperature: 160℃ for 6 seconds, with pressure set to level four or higher.

- Applications: Suitable for materials that are not resistant to high temperatures, such as nylon, leather, heat-sensitive fibers, and other special materials.

High-Temperature Resistant DTF Powder

- Particle size: 100-200μm

- Features: Exhibits excellent high-temperature resistance, high melting point, and strong heat resistance. Remains stable at high temperatures and is not easily deformed or faded.

- Heat pressing temperature: 160℃ for 6 seconds, with pressure set to level four or above.

- Applications: Suitable for industrial workwear, heat-resistant fabrics, and applications requiring high-temperature curing.

BB DTF Hot Melt Powder

- Particle size: 100-130μm

- Features: Uniform particle size, stable adhesion, excellent overall performance, and good printing results and coverage.

- Heat pressing temperature: 160℃ for 6 seconds, with pressure set to level four or higher.

- Applications: Suitable for textile printing with specific requirements, meeting customers’ special needs for pattern detail and quality.

KingJet White DTF Powder, Black DTF Powder, and Other Powders: Features and Applications

| Types | Features and Applications |

| White DTF Powder | 100–200μm, offering excellent coverage to effectively prevent the base fabric color from bleeding and enhance pattern purity |

| Black DTF Powder | 80–170μm, with strong coverage on a black base, designed specifically for black or dark fabrics to prevent pattern penetration |

| Fine DTF Powder | 0–80μm, extremely fine particle size, soft to the touch, best used on lightweight fabrics |

| Medium-Fine DTF Powder | 80–170μm, general-purpose powder, uniform melting, highly adaptable, cost-effective, suitable for everyday clothing such as T-shirts, sweatshirts, and cotton-polyester blends |

| Medium DTF Powder | 100–200μm, strong adhesion, suitable for coarse-textured fabrics, good abrasion resistance, suitable for denim, canvas bags, work clothes, and shoe materials |

| Silicone DTF Powder | 100–200μm, good compatibility with silicone surface, not easy to peel off, strong adhesion, commonly used in outdoor equipment, waterproof clothing, etc |

| Reduce White Ink DTF Powder | 100–200μm, improve white ink coverage, reduce ink usage, and enhance printing efficiency |

| Low-Temperature DTF Powder | 100–200μm, low melting point, suitable for high-temperature sensitive fabrics |

| High-Temperature Resistant DTF Powder | 100–200μm, can withstand high-temperature curing, does not deform or yellow |

| BB DTF Powder | 100–130μm, soft to the touch, good elasticity, specially designed for specific clothing |

The Importance of DTF Powder in DTF Textile Printing

1. Ensuring Adhesion

- DTF powder is the bridge between DTF ink and fabric. Without powder, ink cannot directly adhere to the fabric.

- After the powder melts, a strong bonding layer is formed to prevent the pattern from falling off easily.

2. Enhance Durability

- High-quality DTF powder ensures that the print remains intact after repeated washing and stretching, without cracking or fading.

- Suitable for applications requiring high abrasion resistance, such as sportswear and workwear.

3. Improving Hand Feel and Elasticity

- Different particle sizes of DTF powder can affect the softness and elasticity of printing.

- DTF fine powder is suitable for fine patterns and has a softer hand feel, while DTF medium powder is more abrasion-resistant and suitable for denim or bags.

4. Enhancing Print Quality

- DTF powder can make patterns more vibrant in color and have clearer edges.

- Choosing the appropriate powder types can significantly improve t-shirt printing quality.

KingJet DTF Hot Melt Powder Parameters

| Name | DTF Hot Melt Adhesive Powder |

| Material | TPU |

| Types | White DTF powder, black DTF powder, fine DTF powder, medium-fine DTF powder, medium DTF powder, silicone DTF powder, reduced white ink DTF powder, low-temperature DTF powder, high-temperature resistant DTF powder, etc. |

| Particle Size | 0-200μm |

| Capacity | 1kg/bag |

| Heat Pressing Temperature | Approximately 160℃ |

| Features | Excellent washability, soft handfeel, good elasticity, non-polluting |

| Applications | Cotton, polyester, nylon, denim, and other fabrics |

Other DTF consumables

Start Your Business

We would love to speak with you.

Contact us anytime for personalized services.