How To Choose The Right DTF Transfer Film?

Author : KingJet

2024-10-09

DTF transfer film, an innovative material, can be used as a medium for DTF transfer in the field of printing and personalized customization. The pattern can be transferred to dark and light fabrics of almost all materials through a heat press. It has the characteristics of bright colors, high efficiency, flexibility, and low cost and is favored by many textile printing industry manufacturers.

Table of Contents

What is DTF transfer film?

DTF transfer film, the full name of “direct-to-film transfer film”, is a special film with coating, especially used in the DTF (direct-to-film) printing process. Thermal transfer technology transfers the pattern directly to fabric or other materials.

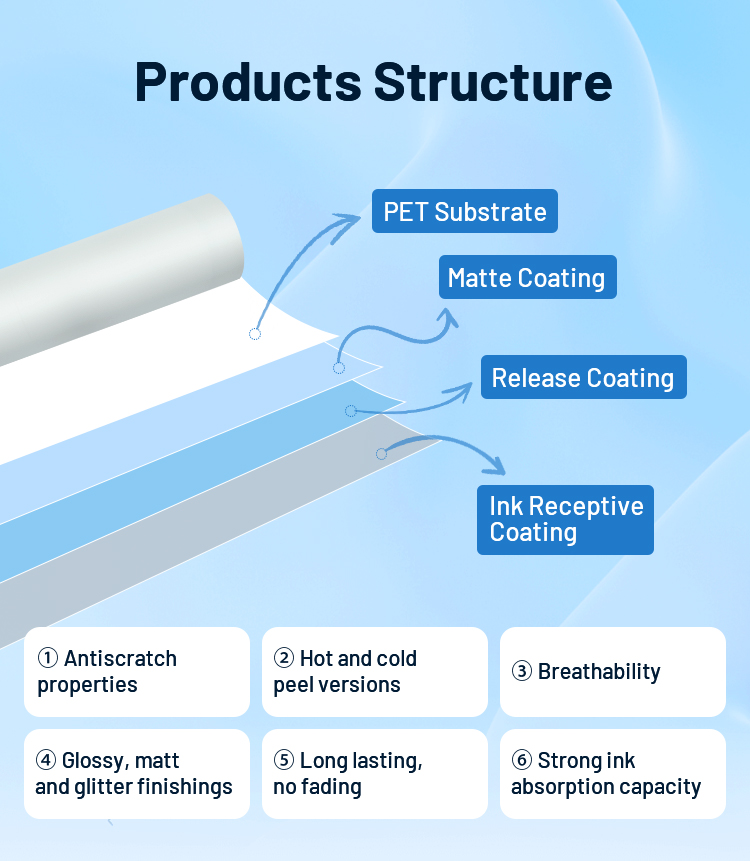

DTF transfer film is usually composed of a multi-layer structure such as a base layer, release layer, adhesive layer, printing layer, protective layer, and antistatic layer. It has the advantages of high definition, bright colors, washability, and wear resistance, and has become an ideal choice for current personalized customization and mass production.

What is a good quality DTF transfer film?

High-quality DTF transfer film has the following significant characteristics:

Strong ink absorption ability: It is suitable for all water-based pigment inks on the market, and 100% of the ink can be printed at will without ink gathering or ink flow.

Clean peeling: The transfer film does not leave ink, the pattern does not leave coating, and it is easy and clean to peel.

Dry film surface: After shaking the powder, the picture is the picture, the powder is the powder, the place with ink is sticky, and the place without ink is clean.

High definition: After the pattern is transferred, the details are clear and the color reproduction is high.

Washable and wear-resistant: The transferred pattern remains intact and bright after multiple washing and friction.

What are the types of DTF transfer films?

DTF transfer films can be divided into many types according to different classification standards (peeling temperature, coating process, visual effect). The following are some common types of DTF PET films:

According to the peeling temperature

Cold peeling DTF film

Cold peeling DTF film needs to wait for the film to cool to a certain temperature (usually 30 seconds or the film surface temperature is lower than 55°C) after the hot stamping is completed before it can be easily torn off.

This kind of film product has good stability and a matte color effect, which is very suitable for use on special fabrics (such as coated fabrics, canvas, flannel, and other rough fabrics).

Because this kind of fabric has sufficient time to restore its flatness after hot pressing, the use of cold peeling DTF film has sufficient time to restore its flatness.

Hot-peel DTF film

Hot-peel DTF film is a PET heat transfer film that can be peeled off after hot stamping is completed while the heat transfer film has not cooled down (usually within 10 seconds after hot stamping, when the film surface temperature is greater than 100℃), without waiting for it to cool down. Using hot-peel DTF film can save time waiting for the heat transfer film to cool down and improve the efficiency of mass production printing.

However, if it is not torn off in time, the cooled glue may stick to the clothes, making it difficult to tear off, and even causing problems such as pattern residue. In general, hot-peel DTF film has strict requirements on the time, temperature, and pressure of hot stamping.

According to the coating process

Glossy DTF film: also known as single-sided DTF film. Only one side is coated DTF film, and the other side is glossy PET-based film. The surface is smooth and has good gloss, which is suitable for printing bright patterns.

Matte DTF film: also known as double-sided DTF film. This does not mean that you can print on both sides. You can only print on one side, and the other side is also matte frosted. This is to increase friction during the printing process, making it more stable, and preventing the film from slipping and affecting the printing effect. After the surface is matte-treated, the color is soft and suitable for printing low-key patterns.

According to visual effects

Luminous DTF film: It can emit light in the dark and is used to make various creative T-shirt clothing designs.

Temperature change DTF film: As the temperature changes, the color of the pattern will change, bringing novel and interesting visual effects.

Glitter gold DTF film: Inlaid with shining golden particles, like stars, adds a touch of luxury and gorgeousness to the pattern.

Colorful reflective DTF film: It can reflect a variety of colors under light, as gorgeous as a rainbow, bringing a strong visual impact to the pattern.

Chameleon DTF film: As the viewing angle changes, the color of the pattern will change, with a unique visual effect.

Polyhedron DTF film: The surface has a prism-like effect, which can refract a variety of light and is suitable for making three-dimensional patterns.

Gradient DTF film: The color of the pattern gradually changes, bringing a richer sense of layering and visual enjoyment to the design.

Gold/silver stamping DTF film: Through the gold or silver hot stamping process, add gold or silver effects to the pattern to enhance the overall texture.

These different types of DTF PET films can meet your diverse needs for pattern effects, making DTF transfer films more widely used in personalized customization and mass production.

In addition, if you want to know more about DTF PET films with special effects, you can check this article: special DTF film.

How to identify the quality of DTF transfer films?

When choosing DTF transfer films, quality is a crucial factor. Here are some ways to identify the quality of DTF transfer films:

Transparency

High-quality DTF transfer films should have good transparency, which helps ensure the clarity and color reproduction of the pattern after transfer. The higher the transparency, the more accurately the details and colors of the pattern can be presented.

Generally speaking, DTF films are divided into 75μ and 100μ, indicating the thickness of the coating film. Usually, 75u DTF films are sufficient to meet most printing needs, while 100u DTF films are suitable for higher-standard printing.

Coating quality

The coating quality of DTF transfer films directly affects its ink absorption ability and ink adhesion. High-quality coatings should be uniform and delicate, without impurities and bubbles. Such a coating can ensure uniform absorption of ink and avoid problems such as ink leakage, fading or water seepage.

Powder shaking effect

The powder shaking effect refers to whether the edge of the pattern of the DTF transfer film is clean and free of residue after printing. After printing and shaking powder, the edge of the pattern of a high-quality DTF transfer film should be clean and free of powder residue. This helps to improve the overall aesthetics and quality of the pattern.

Peeling smoothness

Peeling smoothness refers to the ease with which the DTF transfer film can be peeled off from fabric or other materials after transfer. A high-quality DTF transfer film should be easy to peel off, and the pattern should be intact after peeling. The quality of the peeling effect directly affects the firmness and durability of the pattern after transfer.

High temperature resistance

DTF transfer film needs to withstand high-temperature treatment during printing and transfer. Therefore, high-temperature resistance is one of the important indicators for measuring the quality of DTF transfer film. A high-quality DTF transfer film should be able to withstand high-temperature treatment without yellowing, wrinkling, or deformation.

Through the above identification, you can quickly choose a high-quality DTF transfer film to ensure the quality and effect of the printed product.

Conclusion

DTF transfer film plays an important role as an innovative medium for DTFT T-shirt printing. Therefore, when choosing a suitable DTF transfer film, its transparency, coating uniformity, neatness after shaking powder, smoothness of peeling, and high-temperature resistance should be considered.

At the same time, it is also necessary to carefully select the appropriate DTF PET film type and size according to the specific application scenario to ensure the best printing effect.

If you still don’t know how to choose the right DTF transfer film, you can contact the professional KingJet team to get relevant advice.

FAQ

What fields are DTF transfer films mainly used in?

DTF transfer film is widely used in textile printing and dyeing, clothing production printing, etc. Whether T-shirts, sweatshirts, sportswear, and other clothing and accessories, or shoes, hats, canvas bags, umbrellas, etc., DTF transfer film can provide high-quality printing effects.

What are the advantages of DTF transfer film compared with traditional printing film?

Compared with traditional printing films, DTF transfer films have the following advantages:

First, the colors are brighter, and a special coating is used to ensure uniform ink absorption and full colors.

Second, it is washable and wear-resistant, and the transferred pattern remains intact and bright after multiple washing and friction.

Third, it is easy to operate, the transfer process is simple and fast, and it is suitable for mass production and personalized customization.

Fourth, it is environmentally friendly and safe, meets environmental standards, is harmless to the human body, and can be degraded or recycled.

How to choose the right DTF transfer film?

Choosing the right DTF transfer film requires consideration of a number of factors, including the type of print material, the need for pattern effects, and the production environment.

For example, for fabrics with rough texture, cold peel DTF films can be selected; for scenarios requiring efficient mass production, hot peel or second tear films can be selected.

In addition, attention needs to be paid to the performance indicators of DTF transfer films, such as ink-absorbing capacity, coating quality, powder shaking effect, peeling smoothness, and high-temperature resistance.

What is the market prospect of DTF transfer film?

With the growing demand for personalized customization and mass production, DTF transfer film, as a high-quality printing material, has shown unique charm and broad application prospects in the field of clothing and textiles.

For example, the new special DTF film can provide unique visual effects for T-shirt printing.