What Is Sublimation Printer? Do You Need It?

Author : KingJet

2024-07-31

In recent years, with the development of new printing technology, various printers have emerged in an endless stream, such as DTF printing, UV DTF printing, UV flatbed printing, etc.

However, among many printing devices, sublimation printer have become the first choice for enterprises to maximize printing profits with their high-quality image output. So, what is a sublimation printer? In what fields can it be applied? Do you need it? The following will be introduced in detail:

Table of Contents

What Is Sublimation Printer?

According to the literal understanding, a sublimation printer is a high-end printing device that uses sublimation technology to directly convert solid pigments into gas and fix them on the printing medium.

Its biggest feature is that it can print photos and images with bright colors, rich details, and close-to-natural colors.

Compared with inkjet printers or other traditional printers, sublimation printers use pressure and heat to directly turn sublimation ink into gas, not liquid, and then penetrate into the target material and leave a permanent mark. Because it is integrated with the fabric instead of being laid on the fabric’s surface, it has significant advantages in color expression and durability.

How Does Sublimation Printer Work?

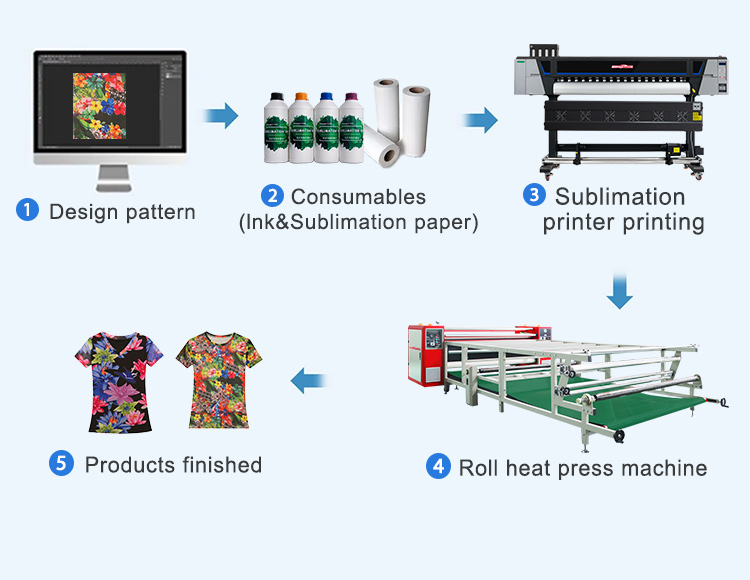

When printing with a sublimation printer, you need a dedicated printer, special ink, sublimation transfer paper, and heat press, etc. The specific printing process is also very simple:

Step 1: Design the pattern

Design the pattern you want to print, and make sure the pattern format is correct and within the printing range of the printer.

Step 2: Sublimation printing

Use a sublimation printer and special sublimation ink to print the designed pattern directly onto special sublimation paper.

Step 3: Transfer

Put the just-printed transfer paper and the target material (such as T-shirts, sportswear, etc.) into a special heat press, and then under the action of pressure and heat, the ink directly turns into gas, penetrates the T-shirt, and merges with the T-shirt.

At this time, the product printing is completed, and you will get a permanent, bright, and not easy to crack and wear T-shirt.

Application Of Sublimation Printer

The application field of sublimation printers is very wide, covering almost all occasions that require high-quality image output, such as clothing, home decoration, outdoor display, life promotional products, etc.

Clothing

Dye-sublimation printers are very suitable for printing polyester clothing. Through thermal sublimation technology, complex patterns, and color gradients can be printed directly onto textiles to achieve high-quality, durable printing effects. Such as T-shirts, hoodies, sportswear, jerseys, printed dresses, hats, scarves, socks, etc.

Home decoration

Dye-sublimation printers can produce a variety of personalized home decorations, such as pillowcases, tablecloths, curtains, murals, etc. Home decorations printed by thermal sublimation can maintain bright colors and clear patterns for a long time, making the home environment more personalized and unique.

Outdoor products

The images printed by sublimation have strong waterproof and UV resistance and can be used to print outdoor posters, signs, banners, display boards, and other printed materials. In addition, its high-definition and bright color printing effect can also enhance the attractiveness of promotional materials and further enhance the brand’s influence.

Life promotional products

Sublimation printing has good waterproof, light-resistant, and friction-resistant characteristics, and can be applied to mugs, handbags, mouse pads, photo albums, mobile phone cases, and other products.

Advantages And Disadvantages Of Sublimation Printer

Although dye-sublimation printers are widely popular, they also have corresponding advantages and disadvantages.

Advantages

1、Widely used, supporting a variety of printing media, such as printed T-shirts, hoodies, curtains, banners, etc.

2、Bright colors, realistic printing, and high-definition printed images.

3、Very durable, the printed images are not easy to fade, damage, or crack.

4、Flexible printing equipment, supporting personalized creative design single or batch orders.

Disadvantages

1、The printing speed is slower than other printers, and it is not suitable for a large number of continuous printing tasks.

2、The fabric selection is limited, and it is best to print on fabrics made of polyester fibers.

3、There are certain requirements for the printing media, and special dye-sublimation paper needs to be used.

4、There are requirements for the color of the print, which is not suitable for dark or black fabrics, but more suitable for printing light-colored or white products.

Do You Really Need a Sublimation Printer?

Before answering this question, please consider your actual needs and printing effects.

If you are looking for high-quality printing of photo albums, printed T-shirts, and sportswear, and are familiar with sublimation printing, then a sublimation printer is undoubtedly your ideal choice.

If you just need to print some ordinary T-shirts or hoodies, and the printing quality is not high, then a DTF printer (direct-to-film printer) or a DTG printer (direct-to-garment printer) may be more suitable for you because they have lower printing costs, simpler operation, and more cost-effective. Therefore, whether you need a sublimation printer depends on your specific printing needs and related budget.

Before making a decision, be sure to carefully weigh the pros and cons and consult the professional KingJet team for advice.

Conclusion

Sublimation printers are widely popular in the market for their unique printing method and excellent printing performance. It can not only print colorful and detailed images but also has the characteristics of durability and wide applicability.

However, it will have requirements for printing colors and restrictions on fabrics, and users need to weigh their actual needs and budget when choosing.

No matter how you choose, sublimation printers are a good choice for users who pursue high-quality image output.

FAQ

What is sublimation printing?

Sublimation printing is a digital printing technology, also known as thermal transfer printing. The working principle is to use heat energy and pressure to transfer dyes to different materials.

Sublimation printer VS inkjet printer, what is the difference?

Sublimation printer produce prints that are more durable and less prone to fading than inkjet printer.

Sublimation printing transfers the dye into the substrate rather than depositing it on the surface, so the resulting image is more permanent.

How long does clothes printed with sublimation last?

Sublimation printing works by converting solid dyes directly into a gas when exposed to high temperatures, and then ejecting the gas onto the print medium.

So when the fabric is heated, the dye sublimates, turns into a gas, and fuses directly into the fabric. When the dye is embedded in the actual fibers, it creates a permanent print that won’t crack or peel over time.

Sublimation Printer VS DTF Printer, which one lasts longer?

Generally speaking, images printed with sublimation last longer and are less likely to fade, peel or crack. But in reality, there are many factors that affect the duration of images on fabrics, so the lifespan of DTF images may exceed that of sublimation.

Do I need heat press machine for sublimation?

Yes, roller heat press is required for sublimation printing, and the image output is better and more durable after being processed by the roller heat press.