Why Choose DTF Printer To Start Your Garment Business? 5 Advantages

Author : KingJet

2024-08-13

In the field of garment printing, DTF (Direct-to-Film) printers are breaking the limitations of traditional technologies such as screen printing, DTG (Direct-to-Garment), and sublimation printers with their unique charm, and have quickly become a hot trend in the industry.

For entrepreneurs who are eager to open up a world in the garment printing industry, DTF printers are undoubtedly an economical and opportunity-filled choice. It not only enables the precise printing of patterns and the perfect integration of clothing but also greatly reduces the threshold for entrepreneurship, making personalized customization possible.

Therefore, this article will deeply analyze the unique advantages of DTF printers and elaborate on how to use this technology to develop your clothing business and help you gain a foothold in the fierce market competition.

Table of Contents

What is DTF printer?

DTF printer, fully called direct-to-film printer, is an advanced digital printing device that can print high-resolution images directly on a special DTF (Direct-to-Film) film. This film has excellent transfer performance and weather resistance, and can perfectly transfer the printed pattern to clothing of various materials, such as cotton, linen, polyester, etc.

DTF printers combine the flexibility of inkjet printing and the durability of thermal transfer, bringing revolutionary changes to the garment customization industry.

How does DTF work?

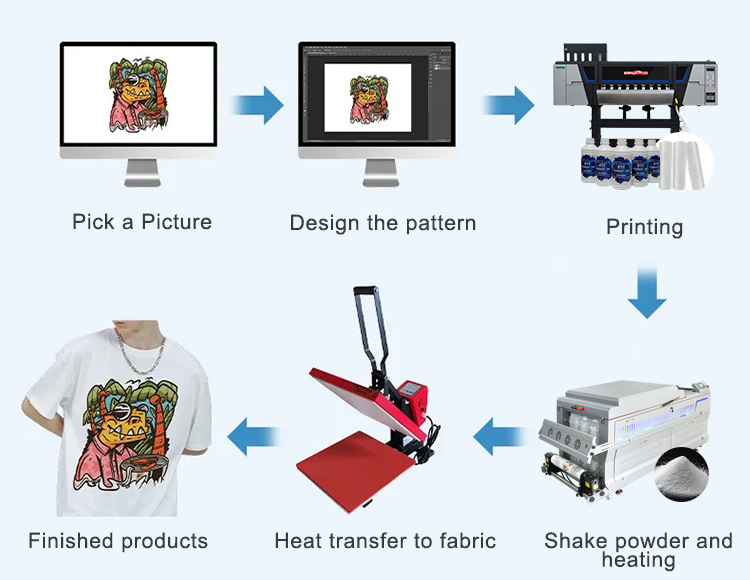

The workflow of DTF printers is simple and efficient, mainly including the following steps:

Design and preparation: First, use graphic design software on the computer to create the pattern and convert it into a format that the printer can recognize through RIP (Raster Image Processor) software.

Printing: Place the DTF film on the printer platform, set the printing parameters, and start the printing program. DTF printers will accurately spray colored ink on the film according to the design pattern to form a high-definition image.

Powder spreading and curing: After printing, the powder shaker will evenly spread the hot melt powder on the surface of the film, and then enter the curing furnace for heating. Under high temperatures, the powder melts and combines with the ink layer on the film to form a solid adhesive layer.

Cutting: Use cutting equipment to cut the film with patterns into separate small pieces according to preset sizes for subsequent transfer.

Heat press transfer: Finally, place the cut DTF film on the garment to be transferred, and apply high temperature and pressure through the hot press to make the pattern firmly attached to the garment. After cooling, tear off the back layer of the film to complete the transfer process.

Application of DTF printers

DTF printers have a wide range of applications, not only limited to clothing customization, but also covering home decoration, advertising logos, gift packaging, and other industries.

In the field of garments, DTF printers provide designers and entrepreneurs with unlimited possibilities with their unique advantages. Whether it is T-shirts, sweatshirts, jeans, or accessories such as canvas bags, hats, socks, etc., DTF printers can achieve personalized customization to meet the diverse needs of consumers.

5 Advantages of DTF printer to start garment business

Personalized customization and differentiated competition

In the fiercely competitive garment market, personalized customization has become an important magic weapon to attract consumers. DTF printers can easily achieve direct printing on almost all fabrics, complex patterns, high-resolution images, and multiple colors, giving each piece of clothing a unique effect.

If you want more unique T-shirt printing, you can use special DTF films, one of which can be superimposed with different films to achieve different visual effects.

This highly personalized customization service can not only quickly design unique clothing styles, and satisfy consumers’ pursuit of uniqueness, but also help your brand stand out from many competitors and form a differentiated competitive advantage.

Efficient production and high-quality output

DTF printers are known for their efficient production processes and high-quality output effects. From design to finished product, the entire process can be completed in a short time, greatly shortening the delivery cycle. This is especially important for the clothing business that seeks to respond quickly to market changes and meet urgent order needs.

At the same time, DTF printers use advanced printing technology to ensure that the clarity, color saturation, and detail restoration of patterns reach extremely high levels, and are not easy to fade and break.

This high-quality output effect not only improves the overall quality of clothing products but also enhances consumers’ purchasing experience and satisfaction.

Therefore, with DTF printers, you can achieve a small-batch, multi-variety production model, flexibly respond to changes in market demand, and improve production efficiency and customer satisfaction.

Easy operation and lower entry threshold

For start-ups and small studios, limited funds and resources are common problems.

DTF printers have become an ideal choice for these companies with their simple operation process and low entry threshold. Users do not need to have a complex printing technology background to quickly get started with DTF printers. Through simple training and learning, you can master its operation methods and maintenance skills.

In addition, the intelligence of DTF printers continues to improve, and many devices are equipped with touchscreen control interfaces and automatic calibration functions, which further reduces the difficulty of operation and labor costs. This enables start-ups and small studios to easily enter the field of personalized clothing customization and achieve rapid development.

Reduce entrepreneurial costs and increase profit margins

Compared with traditional printing technology, DTF printers have significant advantages in cost control.

First, DTF printers use digital printing technology, which does not require plate-making fees and time costs, greatly reducing production costs.

Second, DTF printers support small batch and multi-variety production modes, reducing inventory pressure and capital occupation.

These cost advantages enable entrepreneurs to enter the market at a lower cost and provide competitive pricing strategies.

At the same time, since DTF printers can achieve high-quality output and personalized customization services, they can increase the added value and selling price of products, thereby increasing profit margins. For start-up clothing businesses, DTF printers are undoubtedly an ideal choice to reduce entrepreneurial risks and increase profitability.

Environmental protection and sustainable development

In today’s society, environmental protection and sustainable development have become a global consensus. DTF printers also show their unique advantages in this regard.

First, DTF printers use water-based or environmentally friendly inks, which are less volatile and toxic than traditional solvent-based inks and are less harmful to the environment and human health.

Secondly, DTF printing generates less waste, and most machines are equipped with environmentally friendly smoke purifiers, which can absorb and process the smoke generated during the printing process to reduce environmental pollution.

If you want a more environmentally friendly DTF printer, you can also choose a new powder-free DTF printer (no powder DTF printer). This printer will not produce smoke, is more environmentally friendly, and is healthier for the human body.

How to choose a DTF printer suitable for your garment business?

Choosing a suitable DTF printer is crucial to the success of your clothing business. Here are a few key considerations that will help you make a more accurate choice:

Equipment performance: Examine the printer’s performance indicators such as printing speed, resolution, and color reproduction to ensure that they can meet your production needs.

Size adaptability: Make sure that the size of the selected printer meets your production space requirements, which can not only make efficient use of space but also avoid inconvenience due to excessive size.

Budget considerations: According to your financial situation and long-term investment plan, reasonably set the budget range and find the most cost-effective DTF printer.

Consumables cost: Evaluate the consumables cost of different brands of printers, including ink, paper, etc., which directly affects the subsequent printing cost.

Technical training: Find out whether the supplier provides comprehensive operation training and technical support, which is crucial for getting started quickly and improving production efficiency.

After-sales service: Choose a brand with a complete after-sales service system to ensure that you can get help in time when you encounter problems during the use of the equipment.

Machine maintenance: Consider the difficulty of printer maintenance and the availability of parts to reduce downtime caused by improper maintenance.

Taking the above factors into consideration, you will be able to find the DTF printer that best suits your garment business more accurately.

Conclusion

As mentioned above, DTF printers have many advantages. It can not only help you quickly respond to the needs of the clothing market and provide high-quality personalized customization services, but also reduce the cost of starting a business and increase profit margins.

Therefore, if you are considering entering the field of clothing customization or seeking to improve the competitiveness of your existing business, then choosing a DTF printer that suits your needs is a wise and far-sighted decision. It will bring new development opportunities and unlimited possibilities to your clothing business.

Still don’t know how to choose? Contact the professional KingJet team now.